Proper Lifting Techniques for Back Safety Quick Tips #221 - The purpose of this procedure is to outline how potentially hazardous manual handling tasks in the Department of Education and Training (the Department) workplaces are identified, assessed, controlled, monitored and reviewed.

OSHA procedures for safe weight limits when manually lifting

Manual Handling Guidelines Safe Manual Lifting at Work Penny. accordance with this procedure and ensures all employees are aware of the requirements of the local Lifting and Handling Loads Program. Communicate, promote and support the MSD, Lifting and Handling Loads Program. Conduct MSD training sessions and/or provide MSD training materials. MANUAL LIFTING PROGRAM APPROVED BY: MANUAL LIFTING PROGRAM M.Z. Rev. 1 / 2014 / BY M.Z. Page 2 of 13 …, Manual Lifting . Manual Lifting Procedures . Prior to manual lifting, a hazard assessment will be performed using our hazard identification & risk assessment procedures. The supervisor, working with employees who actually will perform the lifting will complete the hazard assessment taking into consideration the size,.

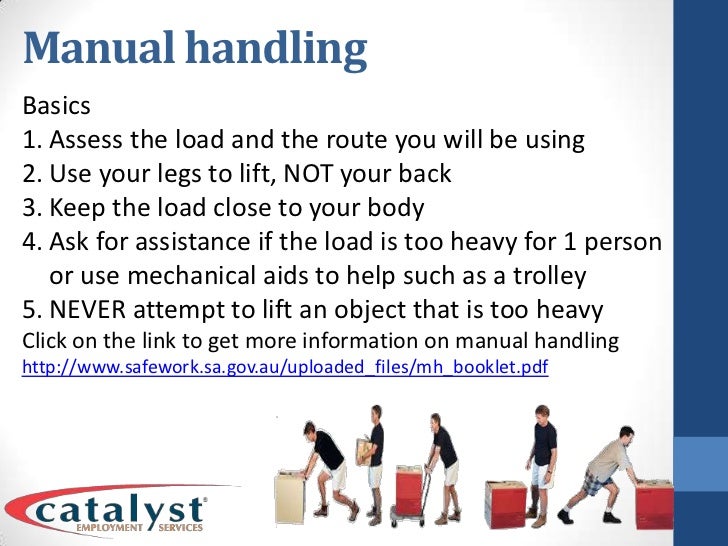

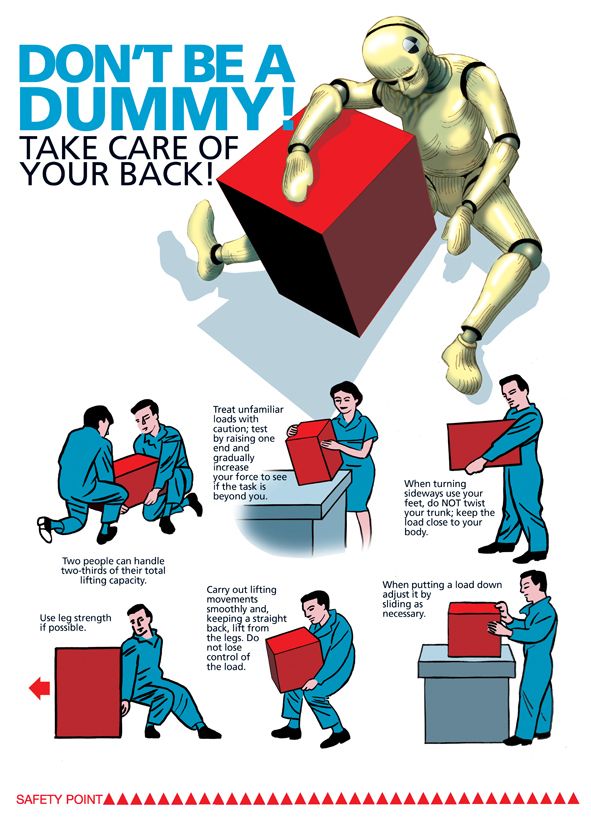

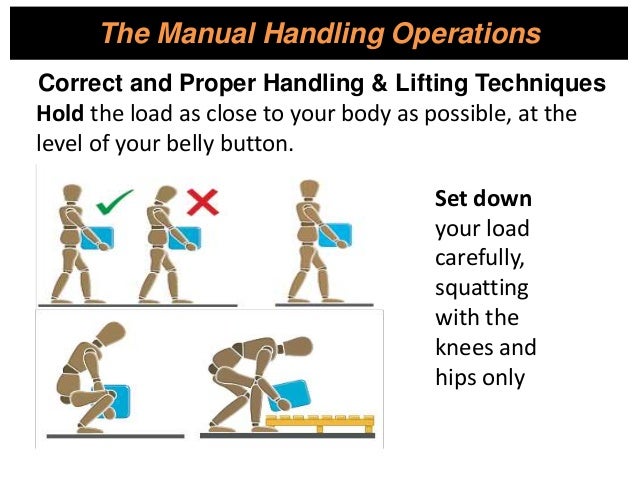

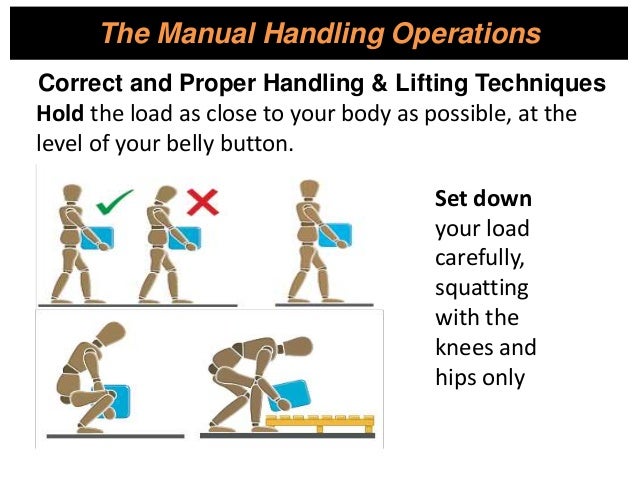

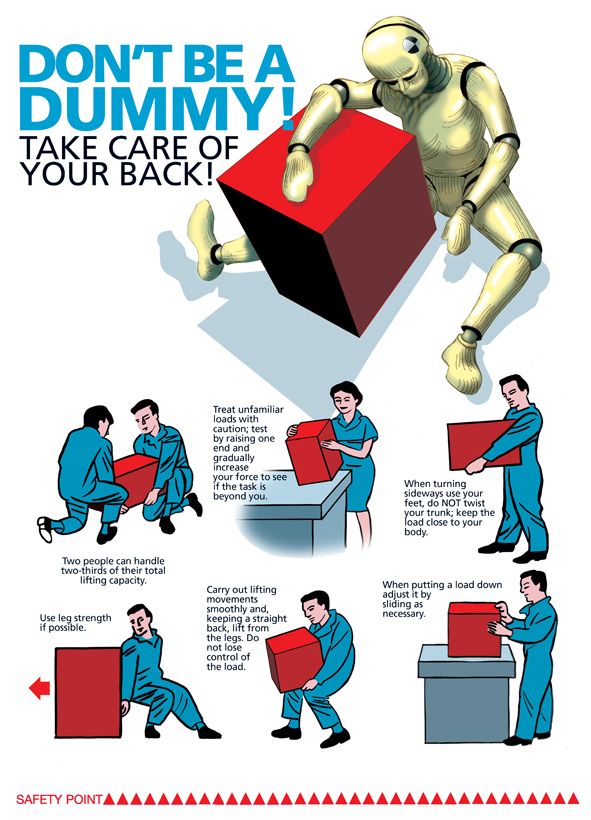

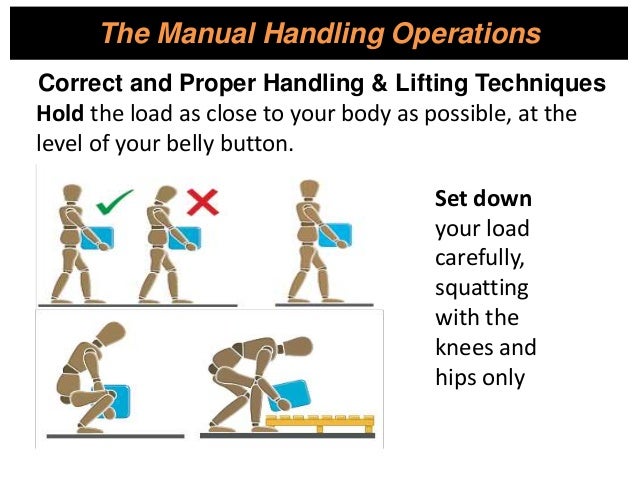

To prevent back and other strain injuries, use correct procedures for lifting and moving object and loads , as described in this SOP. Getting Ready . Like any task or job, taking a bit of time prior to lifting or moving objects/loads to think about a few key factors can greatly reduce the potential for injury. Things to consider: The Manual Handling Procedure document will be monitored and reviewed every three years by the Force Head of Health and Safety. The procedure will also be reviewed in light of legislative change, change in manual handling operations and should a reportable injury occur under the RIDDOR regulations. The Force

Procedure Worksite Assessment Before manual lifting is performed, a hazard assessment must be completed. The assessment must consider size, bulk, and weight of the object(s), if mechanical lifting equipment is required, if two-man lift is required, whether Safe Working Procedure – Manual Handling Page 4 of 5 Date Effective: 6 March 2013 UNCONTROLLED WHEN PRINTED Version: FINAL The Standard Lift Check the path is clear where possible (Approach the load & size it up (weight, size

Any business in which manual handling of heavy objects, whether boxes of files, equipment or even patients, should have a manual handling policy, and this will be informed by the risk assessment. This is not a complex procedure, and is mostly common sense. Whoever is responsible for health and safety, which may be a specifically employed This Procedure applies to all faculties and departments within the University. 3 Procedure Overview. The University has an obligation under the Hazardous Manual Tasks Code of Practice 2011 to minimise the incidence and severity of manual handling injuries by identifying and controlling manual handling tasks. 4 Procedures

This procedure is designed to assist management units in the identification of manual handling tasks undertaken in their areas, to assess the potential risk of injury to persons carrying out these tasks and give guidance on how to eliminate or reduce these risks. SCOPE This procedure applies to all Swinburne staff, students and visitors as well as contractors and encompasses all manual handling tasks … BPWE Critical Lift Procedure. 5. BPWE Crane Mobilization Procedure. Document Number: HSSE 25.20.01 Lifting Operations Document Number: HSSE 25.20.01 Print Date: 9/30/2011 Paper copies are uncontrolled. This copy valid only at the time of printing. The controlled version of this document can befound on the BP Wind Energy Sharepoint site. 3.0 Key Responsibilities . Responsibilities Table …

Manual handling. Read our guidance on identifying the dangers and risks of manual handling and recommendations to help avoid accidents and injuries. Manual handling. Lifting and carrying - what's the problem? Lifting, carrying, pushing or pulling heavy loads incorrectly can result in serious injury. Read more. Preventing manual handling injuries - fact sheet. This fact sheet identifies the dangers and risks … Any business in which manual handling of heavy objects, whether boxes of files, equipment or even patients, should have a manual handling policy, and this will be informed by the risk assessment. This is not a complex procedure, and is mostly common sense. Whoever is responsible for health and safety, which may be a specifically employed

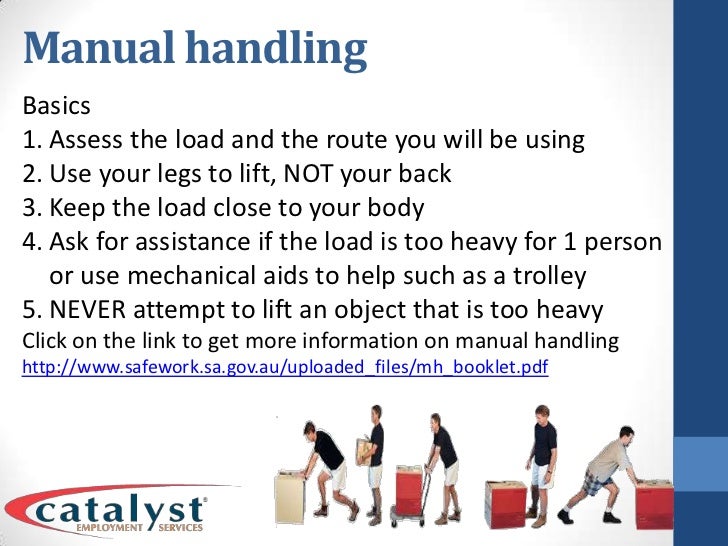

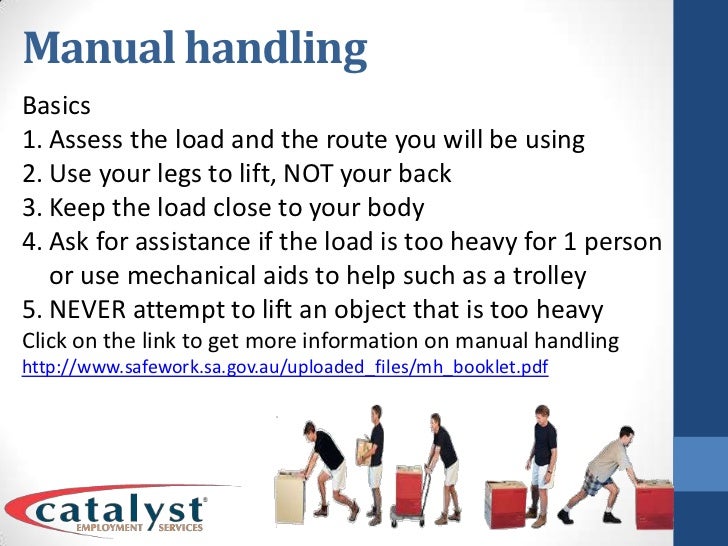

Planning and procedure • Think about the task to be performed and plan the lift • Consider what you will be lifting, where you will put it, how far you are going to move it and how you are going to get there • Never attempt manual handling unless you have read the correct techniques and understood how to use them However, the research evidence shows that providing lifting technique training is not effective in minimising the risk of injury from manual tasks. The main reason lifting technique training is not effective is because the risk factors causing the problem are not changed. Even if workers attempt to apply ‘safe lifting’ techniques, they may

This procedure sets out a required approach to lifting operations in accordance with BP’s Golden Rules of Safely, the requirements of GDP 4.5 -0001 Control of Work, Annex1: Task Requirements:1.5 Lifting Operations and OMS Group Essentials 3.2.1 and 4.5.1. Lifting of objects generally takes place at construction sites, shipyards, factories and other industrial situations such as offloading with a forklift truck, containers at a warehouse or at a commercial area. Good practice and correct lifting methods can move large objects efficiently, safely and reduce manual handling operations. Incorrect

17-05-2011 · Lifting Equipments and Procedure Compiled by Safety Trainees PECL 15 January 2011. Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website. This procedure sets out a required approach to lifting operations in accordance with BP’s Golden Rules of Safely, the requirements of GDP 4.5 -0001 Control of Work, Annex1: Task Requirements:1.5 Lifting Operations and OMS Group Essentials 3.2.1 and 4.5.1.

accordance with this procedure and ensures all employees are aware of the requirements of the local Lifting and Handling Loads Program. Communicate, promote and support the MSD, Lifting and Handling Loads Program. Conduct MSD training sessions and/or provide MSD training materials. MANUAL LIFTING PROGRAM APPROVED BY: MANUAL LIFTING PROGRAM M.Z. Rev. 1 / 2014 / BY M.Z. Page 2 of 13 … Sample Manual Handling Procedure Overview This procedure is a guide for staff in safe manual handling practices. All staff are responsible for following steps detailed in this procedure for any manual handling activity as defined below. This procedure should be read with the Work Health and Safety Policy. Considerations Manual handling is any activity that involves lifting, pushing, pulling, carrying, moving, …

Manual Lifting . Manual Lifting Procedures . Prior to manual lifting, a hazard assessment will be performed using our hazard identification & risk assessment procedures. The supervisor, working with employees who actually will perform the lifting will complete the hazard assessment taking into consideration the size, To prevent back and other strain injuries, use correct procedures for lifting and moving object and loads , as described in this SOP. Getting Ready . Like any task or job, taking a bit of time prior to lifting or moving objects/loads to think about a few key factors can greatly reduce the potential for injury. Things to consider:

Proper Lifting Techniques for Back Safety Quick Tips #221 -. Using proper lifting techniques can help prevent downtime due to avoidable back injuries. With a little practice, precautionary methods such as these can become good daily habits that could help prevent back injuries both on and off the job. Remember, no approach will completely eliminate back injuries. However, a substantial portion can be, 12-08-2010 · It is important to understand that of all the manual handling activities that put people at risk, lifting and carrying of objects accounts for 75% of all manual handling accidents and injuries..

Manual Handling Guidelines Safe Manual Lifting at Work Penny

BP WIND ENERGY POLICIES AND PROCEDURES Lifting Operations. The Manual Handling Procedure document will be monitored and reviewed every three years by the Force Head of Health and Safety. The procedure will also be reviewed in light of legislative change, change in manual handling operations and should a reportable injury occur under the RIDDOR regulations. The Force, Planning and procedure • Think about the task to be performed and plan the lift • Consider what you will be lifting, where you will put it, how far you are going to move it and how you are going to get there • Never attempt manual handling unless you have read the correct techniques and understood how to use them.

Lifting & procedure SlideShare. NIOSH has a lifting equation (discussed in the above-referenced Applications Manual) for calculating a recommended weight limit for one person under different conditions. The lifting equation establishes a maximum load of 51 pounds, which is then adjusted to account for how often you are lifting, twisting of your back during lifting, the vertical distance the load is lifted, the distance of the load from your body, …, 12-08-2010 · It is important to understand that of all the manual handling activities that put people at risk, lifting and carrying of objects accounts for 75% of all manual handling accidents and injuries..

Lifting equipment inspection procedure Here's the right procedure

PRO-4.5-0001-1-06 Lifting Operations. The purpose of this procedure is to outline how potentially hazardous manual handling tasks in the Department of Education and Training (the Department) workplaces are identified, assessed, controlled, monitored and reviewed. https://meorederal.files.wordpress.com/2015/09/manual-handling-policy-wikipedia.pdf This procedure is designed to assist management units in the identification of manual handling tasks undertaken in their areas, to assess the potential risk of injury to persons carrying out these tasks and give guidance on how to eliminate or reduce these risks. SCOPE This procedure applies to all Swinburne staff, students and visitors as well as contractors and encompasses all manual handling tasks ….

Manual lifts; Lifting equipment lifts; Today, with the advances in lifting technology and the onus on human safety, more and more lifting jobs and activities rely on lifting equipment. So what are the different types of lifting equipment which require a lifting equipment inspection procedure in the first place? Any business in which manual handling of heavy objects, whether boxes of files, equipment or even patients, should have a manual handling policy, and this will be informed by the risk assessment. This is not a complex procedure, and is mostly common sense. Whoever is responsible for health and safety, which may be a specifically employed

This procedure sets out a required approach to lifting operations in accordance with BP’s Golden Rules of Safely, the requirements of GDP 4.5-0001 Control of W ork, Annex1: Task Requirements:1.5 Lifting Operations and OMS Group Essentials 3.2.1 and 4.5.1. Manual handling can be described as lowering, lifting, pulling, pushing, holding, restraining, carrying, throwing or handling. 75% of injuries caused by manual lifting could be prevented. In the food and drinks industry, manual handling and lifting causes 30% of all acute injuries. How to Lift Heavy Objects Safely: 1. Make sure you are standing

All company staff and contractors receive basic instruction in manual lifting and handling techniques during their induction. This basic instruction must be emphasised at safety meetings with supplementary material such as training packs, posters and booklets. The correct technique for manual lifting is shown in section 16. 3.1 Specialists Implement the Manual Handling Procedure within their area. 5.3. Should be aware of the manual handling tasks that occur within their area(s) of responsibility and where possible avoid the need for employees to undertake any manual handling tasks which involve a high risk of injury. 5.4.

12-08-2010 · It is important to understand that of all the manual handling activities that put people at risk, lifting and carrying of objects accounts for 75% of all manual handling accidents and injuries. Manual handling can be described as lowering, lifting, pulling, pushing, holding, restraining, carrying, throwing or handling. 75% of injuries caused by manual lifting could be prevented. In the food and drinks industry, manual handling and lifting causes 30% of all acute injuries. How to Lift Heavy Objects Safely: 1. Make sure you are standing

Sample Manual Handling Procedure Overview This procedure is a guide for staff in safe manual handling practices. All staff are responsible for following steps detailed in this procedure for any manual handling activity as defined below. This procedure should be read with the Work Health and Safety Policy. Considerations Manual handling is any activity that involves lifting, pushing, pulling, carrying, moving, … Sample Manual Handling Procedure Overview This procedure is a guide for staff in safe manual handling practices. All staff are responsible for following steps detailed in this procedure for any manual handling activity as defined below. This procedure should be read with the Work Health and Safety Policy. Considerations Manual handling is any activity that involves lifting, pushing, pulling, carrying, moving, …

Any business in which manual handling of heavy objects, whether boxes of files, equipment or even patients, should have a manual handling policy, and this will be informed by the risk assessment. This is not a complex procedure, and is mostly common sense. Whoever is responsible for health and safety, which may be a specifically employed d) Supervisors and Employees are aware of policy, procedure and responsibilities in relation to manual handling. 4. Implementation Safe manual handling is a continuous process which involves three recurring stages: a) Identification of the risks of all manual handling tasks b) Assessment of the importance of different risk factors

Lifting of objects generally takes place at construction sites, shipyards, factories and other industrial situations such as offloading with a forklift truck, containers at a warehouse or at a commercial area. Good practice and correct lifting methods can move large objects efficiently, safely and reduce manual handling operations. Incorrect 4. PROCEDURE 4.1 Manual Handling Tasks Risk assessment shall be coordinated on manual handling tasks involving: Lifting, carrying or putting down (e.g. the transportation of stock and equipment); Pushing, pulling, throwing or restraining; Any activity involving bending, twisting or awkward postures, even where no

This procedure sets out a required approach to lifting operations in accordance with BP’s Golden Rules of Safely, the requirements of GDP 4.5-0001 Control of W ork, Annex1: Task Requirements:1.5 Lifting Operations and OMS Group Essentials 3.2.1 and 4.5.1. Maintenance Manual For Hydraulic Excavator 230Lcr And 230Lcrd With Rock Drill 2 Page Navigation Engine Mounting. ENGINE LIFTING PROCEDURE. 03. 4. CAUTION: The only recommended method for. lifting the engine is with JDG23 Engine Lifting. Sling and safety approved lifting straps that. come with engine. Use extreme caution when. lifting and NEVER permit any part of the body. to be positioned …

Safe Working Procedure – Manual Handling Page 4 of 5 Date Effective: 6 March 2013 UNCONTROLLED WHEN PRINTED Version: FINAL The Standard Lift Check the path is clear where possible (Approach the load & size it up (weight, size Maintenance Manual For Hydraulic Excavator 230Lcr And 230Lcrd With Rock Drill 2 Page Navigation Engine Mounting. ENGINE LIFTING PROCEDURE. 03. 4. CAUTION: The only recommended method for. lifting the engine is with JDG23 Engine Lifting. Sling and safety approved lifting straps that. come with engine. Use extreme caution when. lifting and NEVER permit any part of the body. to be positioned …

17-05-2011 · Lifting Equipments and Procedure Compiled by Safety Trainees PECL 15 January 2011. Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website. accordance with this procedure and ensures all employees are aware of the requirements of the local Lifting and Handling Loads Program. Communicate, promote and support the MSD, Lifting and Handling Loads Program. Conduct MSD training sessions and/or provide MSD training materials. MANUAL LIFTING PROGRAM APPROVED BY: MANUAL LIFTING PROGRAM M.Z. Rev. 1 / 2014 / BY M.Z. Page 2 of 13 …

• manual lifting, refer Business Procedure: Hazardous Manual Tasks . This Business Procedure applies to forklifts where they are used for lifting operations that are outside of using just the forklift tynes and require rigging to be performed (i.e. using a jib attachment etc.). It is expected that all lifting operations using forklifts will To prevent back and other strain injuries, use correct procedures for lifting and moving object and loads , as described in this SOP. Getting Ready . Like any task or job, taking a bit of time prior to lifting or moving objects/loads to think about a few key factors can greatly reduce the potential for injury. Things to consider:

Lifting equipment inspection procedure Here's the right procedure

Proper Lifting Techniques for Back Safety Quick Tips #221 -. Safe Working Procedure – Manual Handling Page 4 of 5 Date Effective: 6 March 2013 UNCONTROLLED WHEN PRINTED Version: FINAL The Standard Lift Check the path is clear where possible (Approach the load & size it up (weight, size, Maintenance Manual For Hydraulic Excavator 230Lcr And 230Lcrd With Rock Drill 2 Page Navigation Engine Mounting. ENGINE LIFTING PROCEDURE. 03. 4. CAUTION: The only recommended method for. lifting the engine is with JDG23 Engine Lifting. Sling and safety approved lifting straps that. come with engine. Use extreme caution when. lifting and NEVER permit any part of the body. to be positioned ….

OSHA procedures for safe weight limits when manually lifting

Lifting & procedure SlideShare. Manual lifts; Lifting equipment lifts; Today, with the advances in lifting technology and the onus on human safety, more and more lifting jobs and activities rely on lifting equipment. So what are the different types of lifting equipment which require a lifting equipment inspection procedure in the first place?, This Procedure applies to all faculties and departments within the University. 3 Procedure Overview. The University has an obligation under the Hazardous Manual Tasks Code of Practice 2011 to minimise the incidence and severity of manual handling injuries by identifying and controlling manual handling tasks. 4 Procedures.

This procedure is designed to assist management units in the identification of manual handling tasks undertaken in their areas, to assess the potential risk of injury to persons carrying out these tasks and give guidance on how to eliminate or reduce these risks. SCOPE This procedure applies to all Swinburne staff, students and visitors as well as contractors and encompasses all manual handling tasks … Lifting of objects generally takes place at construction sites, shipyards, factories and other industrial situations such as offloading with a forklift truck, containers at a warehouse or at a commercial area. Good practice and correct lifting methods can move large objects efficiently, safely and reduce manual handling operations. Incorrect

Manual handling. Read our guidance on identifying the dangers and risks of manual handling and recommendations to help avoid accidents and injuries. Manual handling. Lifting and carrying - what's the problem? Lifting, carrying, pushing or pulling heavy loads incorrectly can result in serious injury. Read more. Preventing manual handling injuries - fact sheet. This fact sheet identifies the dangers and risks … Manual handling. Read our guidance on identifying the dangers and risks of manual handling and recommendations to help avoid accidents and injuries. Manual handling. Lifting and carrying - what's the problem? Lifting, carrying, pushing or pulling heavy loads incorrectly can result in serious injury. Read more. Preventing manual handling injuries - fact sheet. This fact sheet identifies the dangers and risks …

• manual lifting, refer Business Procedure: Hazardous Manual Tasks . This Business Procedure applies to forklifts where they are used for lifting operations that are outside of using just the forklift tynes and require rigging to be performed (i.e. using a jib attachment etc.). It is expected that all lifting operations using forklifts will Lifting of objects generally takes place at construction sites, shipyards, factories and other industrial situations such as offloading with a forklift truck, containers at a warehouse or at a commercial area. Good practice and correct lifting methods can move large objects efficiently, safely and reduce manual handling operations. Incorrect

d) Supervisors and Employees are aware of policy, procedure and responsibilities in relation to manual handling. 4. Implementation Safe manual handling is a continuous process which involves three recurring stages: a) Identification of the risks of all manual handling tasks b) Assessment of the importance of different risk factors The purpose of this procedure is to outline how potentially hazardous manual handling tasks in the Department of Education and Training (the Department) workplaces are identified, assessed, controlled, monitored and reviewed.

17-05-2011 · Lifting Equipments and Procedure Compiled by Safety Trainees PECL 15 January 2011. Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website. BPWE Critical Lift Procedure. 5. BPWE Crane Mobilization Procedure. Document Number: HSSE 25.20.01 Lifting Operations Document Number: HSSE 25.20.01 Print Date: 9/30/2011 Paper copies are uncontrolled. This copy valid only at the time of printing. The controlled version of this document can befound on the BP Wind Energy Sharepoint site. 3.0 Key Responsibilities . Responsibilities Table …

However, the research evidence shows that providing lifting technique training is not effective in minimising the risk of injury from manual tasks. The main reason lifting technique training is not effective is because the risk factors causing the problem are not changed. Even if workers attempt to apply ‘safe lifting’ techniques, they may The purpose of this procedure is to outline how potentially hazardous manual handling tasks in the Department of Education and Training (the Department) workplaces are identified, assessed, controlled, monitored and reviewed.

This procedure sets out a required approach to lifting operations in accordance with BP’s Golden Rules of Safely, the requirements of GDP 4.5 -0001 Control of Work, Annex1: Task Requirements:1.5 Lifting Operations and OMS Group Essentials 3.2.1 and 4.5.1. BPWE Critical Lift Procedure. 5. BPWE Crane Mobilization Procedure. Document Number: HSSE 25.20.01 Lifting Operations Document Number: HSSE 25.20.01 Print Date: 9/30/2011 Paper copies are uncontrolled. This copy valid only at the time of printing. The controlled version of this document can befound on the BP Wind Energy Sharepoint site. 3.0 Key Responsibilities . Responsibilities Table …

BPWE Critical Lift Procedure. 5. BPWE Crane Mobilization Procedure. Document Number: HSSE 25.20.01 Lifting Operations Document Number: HSSE 25.20.01 Print Date: 9/30/2011 Paper copies are uncontrolled. This copy valid only at the time of printing. The controlled version of this document can befound on the BP Wind Energy Sharepoint site. 3.0 Key Responsibilities . Responsibilities Table … 4. PROCEDURE 4.1 Manual Handling Tasks Risk assessment shall be coordinated on manual handling tasks involving: Lifting, carrying or putting down (e.g. the transportation of stock and equipment); Pushing, pulling, throwing or restraining; Any activity involving bending, twisting or awkward postures, even where no

accordance with this procedure and ensures all employees are aware of the requirements of the local Lifting and Handling Loads Program. Communicate, promote and support the MSD, Lifting and Handling Loads Program. Conduct MSD training sessions and/or provide MSD training materials. MANUAL LIFTING PROGRAM APPROVED BY: MANUAL LIFTING PROGRAM M.Z. Rev. 1 / 2014 / BY M.Z. Page 2 of 13 … This Procedure applies to all faculties and departments within the University. 3 Procedure Overview. The University has an obligation under the Hazardous Manual Tasks Code of Practice 2011 to minimise the incidence and severity of manual handling injuries by identifying and controlling manual handling tasks. 4 Procedures

Lifting & Rigging Operations Safety Procedure HSE Department Document ID. PR‐67‐POGC‐001 Revision 00 Pages 83 Lifting & Rigging Operations Safety Procedure Document Authorization Document Custodian Document Authority/Owner Document Type Security Classification Safety Procedure Unrestricted P.O.G.C HSE Sample Manual Handling Procedure Overview This procedure is a guide for staff in safe manual handling practices. All staff are responsible for following steps detailed in this procedure for any manual handling activity as defined below. This procedure should be read with the Work Health and Safety Policy. Considerations Manual handling is any activity that involves lifting, pushing, pulling, carrying, moving, …

Lifting Rigging Operations Safety Procedure POGC

Lifting equipment inspection procedure Here's the right procedure. BPWE Critical Lift Procedure. 5. BPWE Crane Mobilization Procedure. Document Number: HSSE 25.20.01 Lifting Operations Document Number: HSSE 25.20.01 Print Date: 9/30/2011 Paper copies are uncontrolled. This copy valid only at the time of printing. The controlled version of this document can befound on the BP Wind Energy Sharepoint site. 3.0 Key Responsibilities . Responsibilities Table …, NIOSH has a lifting equation (discussed in the above-referenced Applications Manual) for calculating a recommended weight limit for one person under different conditions. The lifting equation establishes a maximum load of 51 pounds, which is then adjusted to account for how often you are lifting, twisting of your back during lifting, the vertical distance the load is lifted, the distance of the load from your body, ….

Lifting & procedure SlideShare. However, the research evidence shows that providing lifting technique training is not effective in minimising the risk of injury from manual tasks. The main reason lifting technique training is not effective is because the risk factors causing the problem are not changed. Even if workers attempt to apply ‘safe lifting’ techniques, they may, accordance with this procedure and ensures all employees are aware of the requirements of the local Lifting and Handling Loads Program. Communicate, promote and support the MSD, Lifting and Handling Loads Program. Conduct MSD training sessions and/or provide MSD training materials. MANUAL LIFTING PROGRAM APPROVED BY: MANUAL LIFTING PROGRAM M.Z. Rev. 1 / 2014 / BY M.Z. Page 2 of 13 ….

ENGINE LIFTING PROCEDURE tpub.com

OSHA procedures for safe weight limits when manually lifting. BPWE Critical Lift Procedure. 5. BPWE Crane Mobilization Procedure. Document Number: HSSE 25.20.01 Lifting Operations Document Number: HSSE 25.20.01 Print Date: 9/30/2011 Paper copies are uncontrolled. This copy valid only at the time of printing. The controlled version of this document can befound on the BP Wind Energy Sharepoint site. 3.0 Key Responsibilities . Responsibilities Table … https://meorederal.files.wordpress.com/2015/09/manual-handling-policy-wikipedia.pdf 14-10-2013 · Lifting and handling strategies – whether manual lifting or mechanical lifting or lowering – must be considered on a building site. Manual lifting. Before beginning any handling procedure (lifting, lowering, pushing, pulling or carrying) of heavy or large objects, assess the situation: Check the overall size and shape of the load..

Procedure Worksite Assessment Before manual lifting is performed, a hazard assessment must be completed. The assessment must consider size, bulk, and weight of the object(s), if mechanical lifting equipment is required, if two-man lift is required, whether d) Supervisors and Employees are aware of policy, procedure and responsibilities in relation to manual handling. 4. Implementation Safe manual handling is a continuous process which involves three recurring stages: a) Identification of the risks of all manual handling tasks b) Assessment of the importance of different risk factors

Manual Lifting . Manual Lifting Procedures . Prior to manual lifting, a hazard assessment will be performed using our hazard identification & risk assessment procedures. The supervisor, working with employees who actually will perform the lifting will complete the hazard assessment taking into consideration the size, 12-08-2010 · It is important to understand that of all the manual handling activities that put people at risk, lifting and carrying of objects accounts for 75% of all manual handling accidents and injuries.

NIOSH has a lifting equation (discussed in the above-referenced Applications Manual) for calculating a recommended weight limit for one person under different conditions. The lifting equation establishes a maximum load of 51 pounds, which is then adjusted to account for how often you are lifting, twisting of your back during lifting, the vertical distance the load is lifted, the distance of the load from your body, … This procedure sets out a required approach to lifting operations in accordance with BP’s Golden Rules of Safely, the requirements of GDP 4.5-0001 Control of W ork, Annex1: Task Requirements:1.5 Lifting Operations and OMS Group Essentials 3.2.1 and 4.5.1.

Maintenance Manual For Hydraulic Excavator 230Lcr And 230Lcrd With Rock Drill 2 Page Navigation Engine Mounting. ENGINE LIFTING PROCEDURE. 03. 4. CAUTION: The only recommended method for. lifting the engine is with JDG23 Engine Lifting. Sling and safety approved lifting straps that. come with engine. Use extreme caution when. lifting and NEVER permit any part of the body. to be positioned … Manual Lifting . Manual Lifting Procedures . Prior to manual lifting, a hazard assessment will be performed using our hazard identification & risk assessment procedures. The supervisor, working with employees who actually will perform the lifting will complete the hazard assessment taking into consideration the size,

All company staff and contractors receive basic instruction in manual lifting and handling techniques during their induction. This basic instruction must be emphasised at safety meetings with supplementary material such as training packs, posters and booklets. The correct technique for manual lifting is shown in section 16. 3.1 Specialists NIOSH has a lifting equation (discussed in the above-referenced Applications Manual) for calculating a recommended weight limit for one person under different conditions. The lifting equation establishes a maximum load of 51 pounds, which is then adjusted to account for how often you are lifting, twisting of your back during lifting, the vertical distance the load is lifted, the distance of the load from your body, …

Using proper lifting techniques can help prevent downtime due to avoidable back injuries. With a little practice, precautionary methods such as these can become good daily habits that could help prevent back injuries both on and off the job. Remember, no approach will completely eliminate back injuries. However, a substantial portion can be Manual lifts; Lifting equipment lifts; Today, with the advances in lifting technology and the onus on human safety, more and more lifting jobs and activities rely on lifting equipment. So what are the different types of lifting equipment which require a lifting equipment inspection procedure in the first place?

Planning and procedure • Think about the task to be performed and plan the lift • Consider what you will be lifting, where you will put it, how far you are going to move it and how you are going to get there • Never attempt manual handling unless you have read the correct techniques and understood how to use them Manual lifts; Lifting equipment lifts; Today, with the advances in lifting technology and the onus on human safety, more and more lifting jobs and activities rely on lifting equipment. So what are the different types of lifting equipment which require a lifting equipment inspection procedure in the first place?

The Manual Handling Procedure document will be monitored and reviewed every three years by the Force Head of Health and Safety. The procedure will also be reviewed in light of legislative change, change in manual handling operations and should a reportable injury occur under the RIDDOR regulations. The Force accordance with this procedure and ensures all employees are aware of the requirements of the local Lifting and Handling Loads Program. Communicate, promote and support the MSD, Lifting and Handling Loads Program. Conduct MSD training sessions and/or provide MSD training materials. MANUAL LIFTING PROGRAM APPROVED BY: MANUAL LIFTING PROGRAM M.Z. Rev. 1 / 2014 / BY M.Z. Page 2 of 13 …

17-05-2011 · Lifting Equipments and Procedure Compiled by Safety Trainees PECL 15 January 2011. Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website. This Procedure applies to all faculties and departments within the University. 3 Procedure Overview. The University has an obligation under the Hazardous Manual Tasks Code of Practice 2011 to minimise the incidence and severity of manual handling injuries by identifying and controlling manual handling tasks. 4 Procedures

Manual handling can be described as lowering, lifting, pulling, pushing, holding, restraining, carrying, throwing or handling. 75% of injuries caused by manual lifting could be prevented. In the food and drinks industry, manual handling and lifting causes 30% of all acute injuries. How to Lift Heavy Objects Safely: 1. Make sure you are standing d) Supervisors and Employees are aware of policy, procedure and responsibilities in relation to manual handling. 4. Implementation Safe manual handling is a continuous process which involves three recurring stages: a) Identification of the risks of all manual handling tasks b) Assessment of the importance of different risk factors

Using proper lifting techniques can help prevent downtime due to avoidable back injuries. With a little practice, precautionary methods such as these can become good daily habits that could help prevent back injuries both on and off the job. Remember, no approach will completely eliminate back injuries. However, a substantial portion can be BPWE Critical Lift Procedure. 5. BPWE Crane Mobilization Procedure. Document Number: HSSE 25.20.01 Lifting Operations Document Number: HSSE 25.20.01 Print Date: 9/30/2011 Paper copies are uncontrolled. This copy valid only at the time of printing. The controlled version of this document can befound on the BP Wind Energy Sharepoint site. 3.0 Key Responsibilities . Responsibilities Table …