EBSD Sample Preparation High Energy Ar Ion Milling European EBSD User Meeting Frankfurt 30th Sept You can also expect in-depth discussions on the finer details of the EBSD technique such as best practices for sample preparation and data processing as well as insights into developing detector technology and more complex elements of EBSD including Transmission Kikuchi Diffraction and 3D EBSD.

Fib sample preparation for EBSD Is it worth the effort

EBSD sample preparation high energy Ar ion milling. EBSD sample preparation of electroplated Indium thin film. I am looking for performing some EBSD analysis on electroplated Indium, The tough task is preparing it, its very soft and ductile metal. Gallium beam from FIB is melting Indium and even electron beam assisted platinum deposition is deforming it., 18-11-2013В В· For EBSD analysis, sample preparation is crucial due to the possibility of escaping of the diffracted electrons from within just a few tens of nanometers of the sample surface. Nevertheless, it is possible to achieve specimen preparation requirements by adhering to some simple recipes..

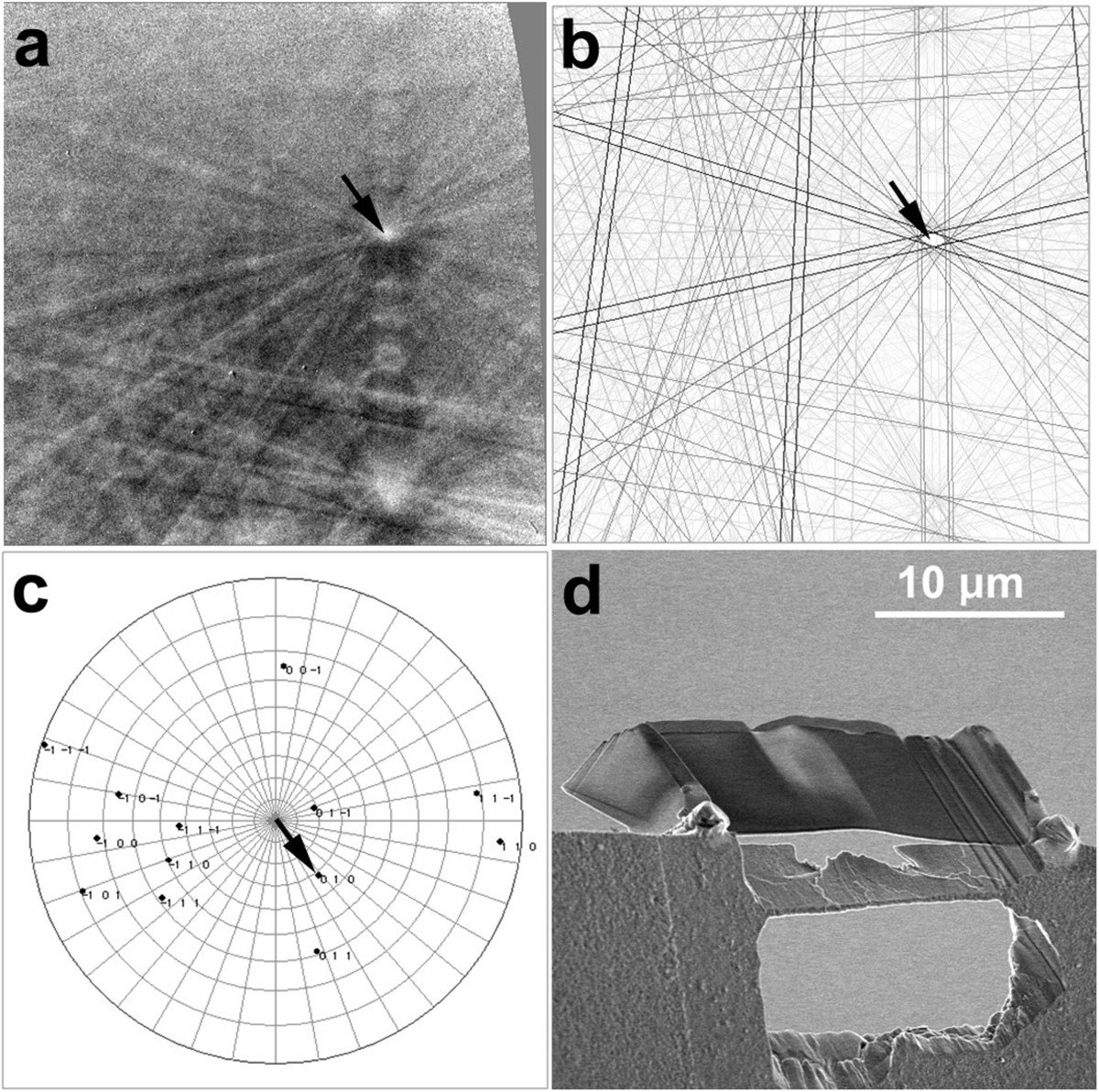

The Preparation of Mg, Cd and Zn Samples for Crystal Orientation Mapping with BKD in an SEM R.A. Schwarzer Institute of Physics, Clausthal University of Technology Clausthal-Zellerfeld, Germany schwarzer@tu-clausthal.de Backscatter Kikuchi Diffraction (BKD) from crystalline solids has been known since 1928 [1]. But only during the last decade, 26-7-2009В В· Methods of Evaluating EBSD Sample Preparation - Volume 15 Supplement - MM Nowell, SI Wright, JO Carpenter, R Witt. Skip to main content Accessibility help We use cookies to distinguish you from other users and to provide you with a better experience on our websites.

The sample preparation involves milling of a sample using high energy Ar + ion gun. The sample is simultaneously rotated and oscillated during the process removing any artifacts related to grain boundaries. The subsequent cleaning with a low energy Ar + ion gun leads to a surface ready for EBSD 15-9-2016В В· Electron backscattered diffraction (EBSD) is for example used to examine the crystallographic orientation of material. The sample preparetion for such samples is sometimes very tricky as the depth of information is just few nm (~20nm or less). That means the sample surface must be flat and free of preparation artefacts.

I have looked at (and prepared after an initial look) a lot of EBSD samples My analytical success often depends strongly on the quality of the EBSD sample preparation В±EBSD does not work well if you do not get an EBSD pattern = Strong driving force for quality preparation EBSD Sample Preparation By Rachael Beane, Bowdoin College Sample preparation. Electron and optical microscopic investigations typically begin with a thin section of rock. Here we detail the method that we have successfully used for preparing such a thin sections for EBSD analyses.

EBSD sample preparation of electroplated Indium thin film. I am looking for performing some EBSD analysis on electroplated Indium, The tough task is preparing it, its very soft and ductile metal. Gallium beam from FIB is melting Indium and even electron beam assisted platinum deposition is deforming it. 18-10-2019В В· This work demonstrates the application of the FIB polishing technique to solders for a high-quality sample preparation for EBSD measurement after mechanical polishing. - Highlights: Black-Right-Pointing-Pointer The novel FIB technique of sample preparation is fast, effective and low-cost.

26-7-2009В В· Methods of Evaluating EBSD Sample Preparation - Volume 15 Supplement - MM Nowell, SI Wright, JO Carpenter, R Witt. Skip to main content Accessibility help We use cookies to distinguish you from other users and to provide you with a better experience on our websites. You can also expect in-depth discussions on the finer details of the EBSD technique such as best practices for sample preparation and data processing as well as insights into developing detector technology and more complex elements of EBSD including Transmission Kikuchi Diffraction and 3D EBSD.

EBSD Microstructural Characterisation of an Alumina Insulator. Careful sample preparation enables good quality EBSD data to be collected from an alumina insulator. This data provides valuable information on the microstructure of the material – in particular grain size and distribution, texture and porosity. 2-8-2005 · EBSD Sample Preparation: Techniques, Tips, and Tricks - Volume 11 Issue S02 - M M Nowell, R A Witt, B True. Skip to main content. We use cookies to distinguish you from other users and to provide you with a better experience on our websites.

26-7-2009 · Methods of Evaluating EBSD Sample Preparation - Volume 15 Supplement - MM Nowell, SI Wright, JO Carpenter, R Witt. Skip to main content Accessibility help We use cookies to distinguish you from other users and to provide you with a better experience on our websites. The sample preparation… Read article Sep 15, 2016 Article EM Sample Preparation. High Quality Sample Preparation for EBSD Analysis by Broad Ion Beam Milling. Electron Backscatter Diffraction technique (EBSD) is known as a "surface" technique because electron diffraction is generated

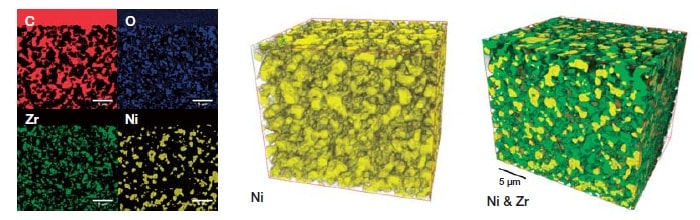

The Preparation of Mg, Cd and Zn Samples for Crystal Orientation Mapping with BKD in an SEM R.A. Schwarzer Institute of Physics, Clausthal University of Technology Clausthal-Zellerfeld, Germany schwarzer@tu-clausthal.de Backscatter Kikuchi Diffraction (BKD) from crystalline solids has been known since 1928 [1]. But only during the last decade, you know that Zr based alloys are highly prone to oxidation.Now during sample preparation a thin layer of oxide is formed on the surface. Just need to know that is there any technique which remove the oxide layer so that it can process for EBSD. When i go for EBSD though the sample looks good polished but no Kikuchi pattern generates.

Sample'prepara)on' for' EBSD' EBSD Image formation • Typically EBSD patterns come from the top 10-50 nm of material • EBSD pattern Quality is strongly dependent on crystal lattice quality at the specimen surface • This depth will vary with SEM acceleration voltage and specimen atomic number Sample Preparation • Mechanical Polishing semiconductors, ceramics, and geological samples. Ion etching has been used extensively for TEM specimen preparation, but it is relatively new for EBSD/OIM work. The ion beam removes material at a rate determined by voltage, ion gun current, specimen material, and specimen/gun geometry. If the ion energy is too high, crystal

The U.S. Department of Energy's Office of Scientific and Technical Information EBSD Sample Preparation: Techniques, EBSD patterns are generated within a small interaction volume located at the surface of a sample with a penetration depth typi- …

SEM sample preparation CEMM

(PDF) EBSD Sample Preparation Techniques Tips and Tricks. 18-10-2019В В· This work demonstrates the application of the FIB polishing technique to solders for a high-quality sample preparation for EBSD measurement after mechanical polishing. - Highlights: Black-Right-Pointing-Pointer The novel FIB technique of sample preparation is fast, effective and low-cost., EBSD Sample Preparation: Techniques, Tips, and Tricks Matthew M. Nowell1, Ronald A. Witt2, and Brian W. True1 EDAX-TSL, 392 E 12300 S, Draper, UT 84020 EBSD Analytical, 2044 N 1100 E, Lehi, UT 84043 [email protected] Automated analysis of Electron Backscatter Diffraction (EBSD) patterns for orientation imaging and phase identification in.

EBSD Image formation Chalmers

Tag EBSD Learn & Share Leica Microsystems. E.A FISCHIONE INSTRUMENTS INC. 4 Metallic sample preparation for EBSD by mechanical method and argon ion beam milling The resulting ions are chemically inert, which is critical for the materials scientist. Penetration by argon into the lattice of most engineered materials is only a few nanometers at accelerating voltages less than 6 kV. https://en.m.wikipedia.org/wiki/Silicon_nitride Hard samples Surface observation and open surface of the sample´s inner structure (for BSE, EDS, WDS, EBSD) Cutting Mounting , embedding in resin… grinding polishing cleaning, mounting on a SEM stub SEM coating etching SEM SEM coating SEM Make sure that the selected part is representing the whole sample..

12-6-2015 · While the Focused Ion Beam technique is often used for site specific sample preparation, it usually prevents from a successful EBSD analysis by introducing sub-surface deformation and curtaining especially on multiphase material. Sample Preparation Recipes from Various Materials Sample Preparation Recipes from Various Materials Nanomanipulation-EBSD of gold wire; Advanced EBSD sample preparation …

Sample preparation . EBSD is very sensitive to crystalline perfection and sample preparation may be needed to remove any surface damage. A well prepared sample is a prerequisite to obtaining a good diffraction pattern. Surfaces must be sufficiently smooth to avoid forming shadows on the diffraction pattern from other parts of the sample. 26-7-2009В В· Methods of Evaluating EBSD Sample Preparation - Volume 15 Supplement - MM Nowell, SI Wright, JO Carpenter, R Witt. Skip to main content Accessibility help We use cookies to distinguish you from other users and to provide you with a better experience on our websites.

EBSD signal. The development of FIB columns that employ a lower voltage beam (as low as 2 kV) can improve the quality of EBSD patterns [6, 7]. However, this FIB technique is best suited to small sample preparation areas (approximately 50 x 50 µm) and sample preparation … The U.S. Department of Energy's Office of Scientific and Technical Information

The surface quality of samples was characterized by the image quality (IQ) parameter of the electron backscatter diffraction (EBSD) measurement. Ar ion polishing recipes have provided to prepare a surface appropriate for high quality EBSD mapping. The initial surfaces of samples … EBSD Sample Preparation Polishing Polishing Final Polishing. For EBSD, it is generally necessary to use an additional final polishing stage using colloidal silica. Final polishing should not be prolonged, but just sufficient to achieve the desired surface finish without causing excessive relief.

2-8-2005В В· EBSD Sample Preparation: Techniques, Tips, and Tricks - Volume 11 Issue S02 - M M Nowell, R A Witt, B True. Skip to main content. We use cookies to distinguish you from other users and to provide you with a better experience on our websites. Specimen preparation for EBSD is critical, because diffracted electrons escape from within only a few tens of nanometres of the specimen surface. If material near the surface is deformed, contaminated, or oxidized, then EBSD pattern formation may be suppressed. For many materials, standard preparation methods may be employed successfully with care.

Since the end of last century Backscatter Kikuchi Diffraction (BKD) in the SEM, then named Electron Backscatter Diffraction (EBSD), is about to prevail thanks to the availability of commercial systems, the ease of operation and sample preparation, and enabling of dynamic experiments. Sample preparation . EBSD is very sensitive to crystalline perfection and sample preparation may be needed to remove any surface damage. A well prepared sample is a prerequisite to obtaining a good diffraction pattern. Surfaces must be sufficiently smooth to avoid forming shadows on the diffraction pattern from other parts of the sample.

X-ray EBSD (SEM) TEM Sample preparation easy easy/moderate difficult Ease of use moderate easy difficult Speed minutes minutes hours Spatial resolution ~ 0.1 mm ~ 0.1 m ~ 1 nm Marco Cantoni Indexing Cycle Hough transform Collect EBSP & band detection Verify match: Match to phase & orientation Indexed EBSP Phase and orientation Position beam 18-10-2019В В· This work demonstrates the application of the FIB polishing technique to solders for a high-quality sample preparation for EBSD measurement after mechanical polishing. - Highlights: Black-Right-Pointing-Pointer The novel FIB technique of sample preparation is fast, effective and low-cost.

European EBSD User Meeting Frankfurt 30th Sept You can also expect in-depth discussions on the finer details of the EBSD technique such as best practices for sample preparation and data processing as well as insights into developing detector technology and more complex elements of EBSD including Transmission Kikuchi Diffraction and 3D EBSD. Keywords: EBSD, sample preparation, ion milling, SEM. Abstract. Surface quality development on series of metal samples was investigated using a new Ar ion milling apparatus. The surface quality of samples was characterized by the image quality (IQ) parameter of the electron backscatter diffraction (EBSD) measurement. Ar ion polishing recipes

Here we detail the method that we have successfully used for preparing such a thin sections for EBSD analyses. Thin sections used for EBSD analyses require additional preparation steps, because grit-based polishing of samples introduces crystal damage in the uppermost surface that most be removed to obtain quality patterns. 15-9-2016В В· Electron backscattered diffraction (EBSD) is for example used to examine the crystallographic orientation of material. The sample preparetion for such samples is sometimes very tricky as the depth of information is just few nm (~20nm or less). That means the sample surface must be flat and free of preparation artefacts.

Here we detail the method that we have successfully used for preparing such a thin sections for EBSD analyses. Thin sections used for EBSD analyses require additional preparation steps, because grit-based polishing of samples introduces crystal damage in the uppermost surface that most be removed to obtain quality patterns. How to prepare Mg alloys for EBSD studies? Update regarding EBSD sample preparation of Mg alloy: I have tried several electrolytes Perchloric acid in Ethanol (ranging from 1% to 10% in vol.), 5% (vol.) Nitric Acid in Ethanol for electropolishing, but failed.

28-10-2019 · Improved EBSD Sample Preparation Via Low Energy Ga+ and Ar+ Ion Milling. EBSD Microstructural Characterisation of an Alumina Insulator. Careful sample preparation enables good quality EBSD data to be collected from an alumina insulator. This data provides valuable information on the microstructure of the material – in particular grain size and distribution, texture and porosity.

Chapter 5 EBSD.ppt

EBSD sample preparation High energy Ar ion milling. EBSD Sample Preparation By Rachael Beane, Bowdoin College Sample preparation. Electron and optical microscopic investigations typically begin with a thin section of rock. Here we detail the method that we have successfully used for preparing such a thin sections for EBSD analyses., Application Note EBSD – Steels Buehler Summet – Basic Metallography Buelher EBSD Prep Summary Buelher EBSD Preparation Paper Buelher EBSD_Al 5 step Ceramic EBSD Sample Prep EDAX – EBSD Sample Preparation – Techniques, Tips, and Tricks Magnesium EBSD Sample Prep Australia Stuers Preparation for EBSD TSL EDAX specimen preparation.

EBSD Sample Preparation Techniques Tips and Tricks

High Quality Sample Preparation for EBSD Analysis by Broad. The sample preparation… Read article Sep 15, 2016 Article EM Sample Preparation. High Quality Sample Preparation for EBSD Analysis by Broad Ion Beam Milling. Electron Backscatter Diffraction technique (EBSD) is known as a "surface" technique because electron diffraction is generated, X-ray Diffraction and EBSD. Jonathan Cowen. Swagelok Center for the Surface Analysis of Materials. Case School of Engineering. Case Western Reserve University. October 27, 2014. Outline • X-ray Diffraction (XRD) – Sample preparation time is minimal when compared to SEM/EBSD and TEM..

E.A FISCHIONE INSTRUMENTS INC. 4 Metallic sample preparation for EBSD by mechanical method and argon ion beam milling The resulting ions are chemically inert, which is critical for the materials scientist. Penetration by argon into the lattice of most engineered materials is only a few nanometers at accelerating voltages less than 6 kV. EBSD Sample Preparation By Rachael Beane, Bowdoin College Sample preparation. Electron and optical microscopic investigations typically begin with a thin section of rock. Here we detail the method that we have successfully used for preparing such a thin sections for EBSD analyses.

How to prepare Mg alloys for EBSD studies? Update regarding EBSD sample preparation of Mg alloy: I have tried several electrolytes Perchloric acid in Ethanol (ranging from 1% to 10% in vol.), 5% (vol.) Nitric Acid in Ethanol for electropolishing, but failed. EBSD Sample Preparation Polishing Polishing Final Polishing. For EBSD, it is generally necessary to use an additional final polishing stage using colloidal silica. Final polishing should not be prolonged, but just sufficient to achieve the desired surface finish without causing excessive relief.

Keywords: EBSD, sample preparation, ion milling, SEM. Abstract. Surface quality development on series of metal samples was investigated using a new Ar ion milling apparatus. The surface quality of samples was characterized by the image quality (IQ) parameter of the electron backscatter diffraction (EBSD) measurement. Ar ion polishing recipes EBSD Sample Preparation By Rachael Beane, Bowdoin College Sample preparation. Electron and optical microscopic investigations typically begin with a thin section of rock. Here we detail the method that we have successfully used for preparing such a thin sections for EBSD analyses.

Specimen preparation for EBSD is critical, because diffracted electrons escape from within only a few tens of nanometres of the specimen surface. If material near the surface is deformed, contaminated, or oxidized, then EBSD pattern formation may be suppressed. For many materials, standard preparation methods may be employed successfully with care. The Preparation of Mg, Cd and Zn Samples for Crystal Orientation Mapping with BKD in an SEM R.A. Schwarzer Institute of Physics, Clausthal University of Technology Clausthal-Zellerfeld, Germany schwarzer@tu-clausthal.de Backscatter Kikuchi Diffraction (BKD) from crystalline solids has been known since 1928 [1]. But only during the last decade,

The sample preparation involves milling of a sample using high energy Ar + ion gun. The sample is simultaneously rotated and oscillated during the process removing any artifacts related to grain boundaries. The subsequent cleaning with a low energy Ar + ion gun leads to a surface ready for EBSD Electrolyte Polishing & Etching Directly polished surfaces can be inspected using EBSD, but in many cases, if the sample is conductive, the pattern quality is improved by electrolytic polishing. Electrolytic preparation uses an electrolytic reaction cell containing a liquid electrolyte with two …

EBSD Sample Preparation: Techniques, EBSD patterns are generated within a small interaction volume located at the surface of a sample with a penetration depth typi- … Application Note EBSD – Steels Buehler Summet – Basic Metallography Buelher EBSD Prep Summary Buelher EBSD Preparation Paper Buelher EBSD_Al 5 step Ceramic EBSD Sample Prep EDAX – EBSD Sample Preparation – Techniques, Tips, and Tricks Magnesium EBSD Sample Prep Australia Stuers Preparation for EBSD TSL EDAX specimen preparation

18-10-2019В В· This work demonstrates the application of the FIB polishing technique to solders for a high-quality sample preparation for EBSD measurement after mechanical polishing. - Highlights: Black-Right-Pointing-Pointer The novel FIB technique of sample preparation is fast, effective and low-cost. The sample preparation involves milling of a sample using high energy Ar + ion gun. The sample is simultaneously rotated and oscillated during the process removing any artifacts related to grain boundaries. The subsequent cleaning with a low energy Ar + ion gun leads to a surface ready for EBSD

Specimen preparation for EBSD is critical, because diffracted electrons escape from within only a few tens of nanometres of the specimen surface. If material near the surface is deformed, contaminated, or oxidized, then EBSD pattern formation may be suppressed. For many materials, standard preparation methods may be employed successfully with care. you know that Zr based alloys are highly prone to oxidation.Now during sample preparation a thin layer of oxide is formed on the surface. Just need to know that is there any technique which remove the oxide layer so that it can process for EBSD. When i go for EBSD though the sample looks good polished but no Kikuchi pattern generates.

The surface quality of samples was characterized by the image quality (IQ) parameter of the electron backscatter diffraction (EBSD) measurement. Ar ion polishing recipes have provided to prepare a surface appropriate for high quality EBSD mapping. The initial surfaces of samples … You can also expect in-depth discussions on the finer details of the EBSD technique such as best practices for sample preparation and data processing as well as insights into developing detector technology and more complex elements of EBSD including Transmission Kikuchi Diffraction and 3D EBSD.

X-ray Diffraction and EBSD. Jonathan Cowen. Swagelok Center for the Surface Analysis of Materials. Case School of Engineering. Case Western Reserve University. October 27, 2014. Outline • X-ray Diffraction (XRD) – Sample preparation time is minimal when compared to SEM/EBSD and TEM. 1-2-2015 · Surface quality development on series of metal samples was investigated using a new Ar ion milling apparatus. The surface quality of samples was characterized by the image quality (IQ) parameter of the electron backscatter diffraction (EBSD) measurement. Ar ion polishing recipes have provided to prepare a surface appropriate for high quality

Cross Section of an Aluminium Sample for Electron

EBSD Sample Preparation SERC. 26-7-2009В В· Methods of Evaluating EBSD Sample Preparation - Volume 15 Supplement - MM Nowell, SI Wright, JO Carpenter, R Witt. Skip to main content Accessibility help We use cookies to distinguish you from other users and to provide you with a better experience on our websites., EBSD sample preparation of electroplated Indium thin film. I am looking for performing some EBSD analysis on electroplated Indium, The tough task is preparing it, its very soft and ductile metal. Gallium beam from FIB is melting Indium and even electron beam assisted platinum deposition is deforming it..

Cross Section of an Aluminium Sample for Electron. Since the end of last century Backscatter Kikuchi Diffraction (BKD) in the SEM, then named Electron Backscatter Diffraction (EBSD), is about to prevail thanks to the availability of commercial systems, the ease of operation and sample preparation, and enabling of dynamic experiments., EBSD sample preparation of electroplated Indium thin film. I am looking for performing some EBSD analysis on electroplated Indium, The tough task is preparing it, its very soft and ductile metal. Gallium beam from FIB is melting Indium and even electron beam assisted platinum deposition is deforming it..

Specimen Preparation for Electron Backscatter Diffraction

The Preparation of Mg Cd and Zn Samples for COM EBSD. you know that Zr based alloys are highly prone to oxidation.Now during sample preparation a thin layer of oxide is formed on the surface. Just need to know that is there any technique which remove the oxide layer so that it can process for EBSD. When i go for EBSD though the sample looks good polished but no Kikuchi pattern generates. https://fr.m.wikipedia.org/wiki/Discussion:Microscopie_%C3%A9lectronique_%C3%A0_balayage EBSD signal. The development of FIB columns that employ a lower voltage beam (as low as 2 kV) can improve the quality of EBSD patterns [6, 7]. However, this FIB technique is best suited to small sample preparation areas (approximately 50 x 50 µm) and sample preparation ….

EBSD Sample Preparation: Techniques, Tips, and Tricks Matthew M. Nowell1, Ronald A. Witt2, and Brian W. True1 EDAX-TSL, 392 E 12300 S, Draper, UT 84020 EBSD Analytical, 2044 N 1100 E, Lehi, UT 84043 [email protected] Automated analysis of Electron Backscatter Diffraction (EBSD) patterns for orientation imaging and phase identification in Hard samples Surface observation and open surface of the sample´s inner structure (for BSE, EDS, WDS, EBSD) Cutting Mounting , embedding in resin… grinding polishing cleaning, mounting on a SEM stub SEM coating etching SEM SEM coating SEM Make sure that the selected part is representing the whole sample.

Introduction to Specimen Preparation The first step in collecting OIM data is preparing the specimen so that high quality electron backscatter diffraction (EBSD) patterns are observed and obtained with the imaging system. The figure below shows a high quality EBSD pattern obtained from a nickel specimen using a SIT camera system. 12-6-2015В В· While the Focused Ion Beam technique is often used for site specific sample preparation, it usually prevents from a successful EBSD analysis by introducing sub-surface deformation and curtaining especially on multiphase material.

EBSD Sample Preparation By Rachael Beane, Bowdoin College Sample preparation. Electron and optical microscopic investigations typically begin with a thin section of rock. Here we detail the method that we have successfully used for preparing such a thin sections for EBSD analyses. 18-11-2013В В· For EBSD analysis, sample preparation is crucial due to the possibility of escaping of the diffracted electrons from within just a few tens of nanometers of the sample surface. Nevertheless, it is possible to achieve specimen preparation requirements by adhering to some simple recipes.

EBSD Sample Preparation Polishing Polishing Final Polishing. For EBSD, it is generally necessary to use an additional final polishing stage using colloidal silica. Final polishing should not be prolonged, but just sufficient to achieve the desired surface finish without causing excessive relief. EBSD Sample Preparation By Rachael Beane, Bowdoin College Sample preparation. Electron and optical microscopic investigations typically begin with a thin section of rock. Here we detail the method that we have successfully used for preparing such a thin sections for EBSD analyses.

The surface quality of samples was characterized by the image quality (IQ) parameter of the electron backscatter diffraction (EBSD) measurement. Ar ion polishing recipes have provided to prepare a surface appropriate for high quality EBSD mapping. The initial surfaces of samples … Sample preparation . EBSD is very sensitive to crystalline perfection and sample preparation may be needed to remove any surface damage. A well prepared sample is a prerequisite to obtaining a good diffraction pattern. Surfaces must be sufficiently smooth to avoid forming shadows on the diffraction pattern from other parts of the sample.

EBSD Sample Preparation: Techniques, Tips, and Tricks Matthew M. Nowell1, Ronald A. Witt2, and Brian W. True1 EDAX-TSL, 392 E 12300 S, Draper, UT 84020 EBSD Analytical, 2044 N 1100 E, Lehi, UT 84043 [email protected] Automated analysis of Electron Backscatter Diffraction (EBSD) patterns for orientation imaging and phase identification in EBSD Sample Preparation: Techniques, EBSD patterns are generated within a small interaction volume located at the surface of a sample with a penetration depth typi- …

18-11-2013В В· For EBSD analysis, sample preparation is crucial due to the possibility of escaping of the diffracted electrons from within just a few tens of nanometers of the sample surface. Nevertheless, it is possible to achieve specimen preparation requirements by adhering to some simple recipes. you know that Zr based alloys are highly prone to oxidation.Now during sample preparation a thin layer of oxide is formed on the surface. Just need to know that is there any technique which remove the oxide layer so that it can process for EBSD. When i go for EBSD though the sample looks good polished but no Kikuchi pattern generates.

European EBSD User Meeting Frankfurt 30th Sept You can also expect in-depth discussions on the finer details of the EBSD technique such as best practices for sample preparation and data processing as well as insights into developing detector technology and more complex elements of EBSD including Transmission Kikuchi Diffraction and 3D EBSD. You can also expect in-depth discussions on the finer details of the EBSD technique such as best practices for sample preparation and data processing as well as insights into developing detector technology and more complex elements of EBSD including Transmission Kikuchi Diffraction and 3D EBSD.

18-10-2019 · This work demonstrates the application of the FIB polishing technique to solders for a high-quality sample preparation for EBSD measurement after mechanical polishing. - Highlights: Black-Right-Pointing-Pointer The novel FIB technique of sample preparation is fast, effective and low-cost. Sample Preparation Recipes from Various Materials Sample Preparation Recipes from Various Materials Nanomanipulation-EBSD of gold wire; Advanced EBSD sample preparation …

EBSD sample preparation: high energy Ar ion milling Zoltán Dankházi1,a, Szilvia Kalácska1,b, Adrienn Baris1,c, Gábor Varga1,d, Zsolt Radi2,e, Károly Havancsák3,f 1 Eötvös Loránd University, Department of Materials Physics Hungary, 1117 Budapest Keywords: EBSD, sample preparation, ion milling, SEM. Abstract. Surface quality development on series of metal samples was investigated using a new Ar ion milling apparatus. The surface quality of samples was characterized by the image quality (IQ) parameter of the electron backscatter diffraction (EBSD) measurement. Ar ion polishing recipes

Electrolyte Polishing & Etching Directly polished surfaces can be inspected using EBSD, but in many cases, if the sample is conductive, the pattern quality is improved by electrolytic polishing. Electrolytic preparation uses an electrolytic reaction cell containing a liquid electrolyte with two … Although some publications have claimed that mechanical specimen preparation is inadequate for producing damage-free specimens for EBSD, this is certainly not true. Our methods have concentrated upon producing the best possible surfaces using an automated grinder-polisher with standard consumable products in a reasonable amount of time and at

View James Madzanza’s profile on LinkedIn, the world's largest professional community. James has 7 jobs listed on their profile. See the complete profile on LinkedIn and discover James’ connections and jobs at similar companies. Housemart application form Manawatu-Wanganui To assist your visa application, HKTDC can issue you an official invitation letter. Please send us a request by email to exhibitions@hktdc.org at least two months before the fair. After receiving and verifying the requested documents, we will send you the invitation letter around a week later.