This manual provides a comprehensive guide for installers, technicians, and end-users to understand and utilize KE2 Therm products effectively. It covers product overview, key features, installation, and troubleshooting.

1.1 Overview of KE2 Therm Solutions

KE2 Therm Solutions offers advanced refrigeration control systems designed for efficiency and reliability. Their products include temperature controllers, defrost systems, and adaptive technology for various applications. With a focus on energy savings, KE2 Therm provides tools for remote monitoring, alarm notifications, and smart access features. The solutions cater to medium and low-temperature environments, ensuring optimal performance. Detailed manuals and guides are available online, covering installation, troubleshooting, and customization. KE2 Therm products are known for their adaptability and compliance with industry standards.

1.2 Purpose of the KE2 Therm Manual

This manual serves as a detailed resource for understanding and utilizing KE2 Therm products. It provides step-by-step instructions, technical specifications, and troubleshooting tips for installers, technicians, and end-users. The manual covers installation, configuration, and maintenance of KE2 Therm controllers, ensuring optimal performance and energy efficiency. It also includes advanced features like remote monitoring and adaptive control technology. By following this guide, users can maximize the functionality and longevity of their KE2 Therm systems, addressing common issues and customizing settings as needed.

Key Features of KE2 Therm Products

KE2 Therm products offer advanced temperature controls, adaptive technology, and energy-efficient solutions for refrigeration systems, ensuring optimal performance and reduced energy consumption.

2.1 Temperature and Defrost Controls

The KE2 Therm system offers precise temperature management and efficient defrost cycles. It supports medium temperature applications with air defrost, ensuring optimal performance. The controller notifies the user when exiting a defrost cycle, simplifying monitoring. Key features include:

- Precise temperature control for consistent refrigeration.

- Energy-efficient defrost cycles to minimize energy use.

- Customizable defrost settings for specific applications.

These controls ensure reliable operation and reduced maintenance, making them ideal for various refrigeration needs.

2.2 Adaptive Control Technology

The KE2 Therm system incorporates advanced Adaptive Control Technology, which optimizes refrigeration performance by adjusting settings in real-time. This technology enhances energy efficiency and ensures consistent temperatures. The kit includes a controller, safety shields, and sensors, providing precise control over defrost cycles and temperature maintenance. It supports medium temperature applications and is designed for easy installation with pre-tested components. This adaptive approach minimizes energy consumption while maintaining optimal system operation.

2.3 Energy Efficiency and Savings

KE2 Therm products are designed to reduce energy consumption while maintaining optimal performance. By utilizing adaptive controls and smart defrost management, these systems minimize unnecessary energy use; Users can achieve significant cost savings through precise temperature regulation and reduced operational cycles. The technology ensures that energy is used efficiently, lowering overall power consumption. This not only benefits the environment but also provides long-term financial savings for businesses. The KE2 Therm system is a cost-effective solution for energy-conscious applications.

Installation and Setup

KE2 Therm controllers offer a straightforward installation process. Use the quick start guide for step-by-step instructions, wiring diagrams, and sensor placement tips to ensure proper setup and functionality.

3.1 Quick Start Guide for KE2 Therm Controllers

The quick start guide provides step-by-step instructions to install and configure KE2 Therm controllers. It covers essential steps like mounting sensors, connecting wires, and setting up the controller. The guide ensures a smooth setup process, helping users achieve optimal system performance quickly. Use it to navigate through initial configurations and get your system operational efficiently.

3.2 Wiring Diagrams and Requirements

Wiring diagrams provide detailed connections for sensors, power, and communication. Ensure correct wire gauges and connections to avoid system issues. Follow diagrams for specific models like KE2 Evap OEM or CaseControllerDisplay. Proper wiring ensures safe and efficient operation. Refer to the manual for precise instructions tailored to your controller model. Incorrect wiring can lead to malfunctions or safety hazards, so double-check connections before powering up the system.

3.3 Mounting and Placement of Sensors

Proper sensor placement is crucial for accurate temperature readings. Mount sensors at least 6 inches away from coils to avoid direct heat interference. Ensure sensors are securely fastened and wires are routed neatly to the controller. Follow manufacturer guidelines for specific sensor types, such as air or coil sensors. Incorrect placement may lead to inaccurate temperature readings or system malfunctions. Always refer to the wiring diagrams for correct sensor connections and positioning to maintain optimal system performance and reliability.

Troubleshooting Common Issues

Identify system alarms, error codes, and perform resets to resolve common issues. Check circuit breakers, wiring connections, and sensor placements for optimal functionality and accurate readings.

4.1 Identifying and Resolving System Alarms

System alarms on KE2 Therm controllers indicate operational issues. Check LED indicators or digital displays for specific error codes. Common alarms include defrost cycle malfunctions, sensor faults, or communication errors. Review the manual for code meanings. Resolve issues by verifying wiring connections, ensuring proper sensor placement, and checking for power disruptions. Reset the controller if necessary. For persistent problems, consult the troubleshooting guide or contact technical support. Regular maintenance can prevent recurring alarms and ensure system reliability.

4.2 Common Error Codes and Solutions

KE2 Therm controllers display error codes to identify system issues. Common codes include E1 for temperature sensor faults, E2 for communication errors, and E3 for power supply problems. Solutions involve checking sensor connections, verifying wiring, or resetting the controller. For E1, ensure sensors are properly mounted and free from damage. For E2, check network cables and ensure proper LAN/WAN configuration. E3 may require checking the power source or circuit breakers. Refer to the manual or contact support for unresolved issues to maintain system efficiency and prevent downtime.

4.3 Resetting the Controller

Resetting the KE2 Therm controller restores it to factory defaults, resolving configuration issues. Power down the system, then press and hold the reset button for 10 seconds while powering up. Release the button and wait for the controller to reboot. Note that this erases custom settings, requiring reprogramming. Use this feature cautiously and only when necessary, as it will clear all user-configured parameters. Always back up settings before performing a reset to avoid data loss and ensure smooth system restoration.

Advanced Configurations

This section covers customizing defrost cycles, adjusting temperature setpoints, and integrating with Smart Access features for enhanced system control and efficiency, tailored to specific user requirements.

5.1 Customizing Defrost Cycles

Customizing defrost cycles in KE2 Therm systems allows users to tailor defrost operations to specific applications. The controller supports various defrost types, including electric and hot gas, and enables adjustments to defrost duration and frequency. This ensures optimal performance by preventing excessive ice buildup while maintaining energy efficiency. Users can configure defrost initiation based on time or demand, and the system provides notifications when exiting a defrost cycle. Detailed instructions for customizing defrost cycles are available in the KE2 Temp Defrost installation manual and related guides.

5.2 Adjusting Temperature Setpoints

Adjusting temperature setpoints in KE2 Therm systems is straightforward, allowing users to fine-tune their refrigeration settings for optimal performance. The controller prompts the user to enter the desired ROOM TEMP and DEFROST TYPE, ensuring precise temperature management. The system also provides notifications when exiting a defrost cycle, maintaining consistent conditions. Users can customize these settings based on specific application needs, ensuring energy efficiency and system reliability. Detailed guidance on adjusting setpoints is available in the KE2 Temp Defrost installation manual and related resources.

5.3 Integrating with Smart Access Features

Integrating KE2 Therm controllers with Smart Access features enhances remote monitoring and control capabilities. Users can set up email/text alarm alerts for instant notifications of system issues, ensuring timely responses. The KE2 Smart Access feature, detailed in bulletins Q.1.34 and A.1.76, allows remote system oversight during off-hours or vacations. LAN/WAN configuration enables network connectivity, and the KE2 Local Area Dashboard (LDA) provides advanced monitoring options. Refer to the user manual for setup instructions and pairing guides to seamlessly integrate these smart features.

Remote Monitoring and Control

KE2 Therm systems offer advanced remote monitoring and control solutions. Set up email/text alarm alerts for instant notifications. Configure LAN/WAN for secure network integration. Utilize KE2 Local Area Dashboard (LDA) for enhanced monitoring. Ensure real-time system oversight and optimal performance.

6.1 Setting Up Email/Text Alarm Alerts

Configure email and text alerts to receive instant notifications for system issues. Enable real-time monitoring of your refrigeration systems. Set up alerts for temperature deviations, defrost cycle completions, and system faults. Ensure uninterrupted oversight of your equipment. Refer to bulletins Q.1.34 and A.1.76 for detailed setup instructions. Customize alert preferences to suit your needs. Stay informed and address issues promptly to maintain optimal performance and prevent downtime.

6.2 Using KE2 Smart Access for Remote Monitoring

KE2 Smart Access enables remote monitoring of your refrigeration systems, ensuring continuous oversight from any location. Access real-time data, system performance metrics, and receive critical updates. This feature allows users to monitor temperature levels, defrost cycles, and system alarms remotely. Compatible with Ethernet controllers, KE2 Smart Access provides a user-friendly interface for seamless monitoring. Stay connected to your equipment 24/7, reducing the need for on-site visits and ensuring optimal system operation. This tool enhances efficiency and peace of mind for system managers.

6.3 LAN/WAN Configuration for Network Connectivity

Configuring LAN/WAN settings ensures seamless network connectivity for KE2 Therm controllers. Assign a static IP address to the controller to enable communication across local and wide-area networks. Use subnet masks and default gateways to define network boundaries. Ensure proper DNS settings for remote access. Secure the connection with a strong password to prevent unauthorized access. Refer to the KE2 Therm Ethernet Controller guide for detailed steps. Proper LAN/WAN setup allows remote monitoring and control, enhancing system management and responsiveness to alerts.

Energy Efficiency and Cost Savings

This section explores how KE2 Therm products optimize energy use through adaptive control and smart defrost cycles, reducing consumption and lowering operational costs.

7.1 How KE2 Therm Products Reduce Energy Consumption

KE2 Therm products reduce energy consumption through adaptive control technology, optimizing defrost cycles, and smart temperature management. These features ensure systems operate efficiently, avoiding unnecessary energy use. By adjusting defrost cycles based on real-time conditions and maintaining precise temperature setpoints, KE2 Therm minimizes waste and lowers operational costs. Additionally, remote monitoring capabilities allow users to identify and address inefficiencies promptly, further enhancing energy savings.

7.2 Calculating ROI for Energy-Efficient Solutions

Calculating ROI for KE2 Therm energy-efficient solutions involves analyzing energy savings, initial investment, and long-term benefits; By comparing pre- and post-installation energy consumption, users can quantify reductions in utility bills. Additionally, maintenance savings from optimized system performance and extended equipment life contribute to ROI. KE2 Therm products often qualify for energy efficiency incentives, further enhancing financial returns. Detailed analysis tools and guidelines are provided to help users evaluate and maximize their investment benefits effectively.

7.3 Optimizing System Performance

Optimizing system performance with KE2 Therm involves adjusting settings like temperature setpoints and defrost cycles to match specific requirements. Regularly updating firmware ensures the latest features and improvements are applied. Cleaning sensors and checking wiring maintains accuracy and reliability. Users can also customize adaptive control parameters to enhance efficiency. Monitoring energy usage patterns helps identify areas for improvement. Proper maintenance and timely software updates ensure the system operates at peak performance, delivering consistent results and maximizing energy savings over time.

Product-Specific Manuals

This section provides detailed guides for specific KE2 Therm products, including installation and operation instructions for controllers, sensors, and accessories. Refer to the respective manuals for in-depth information.

8.1 KE2 Temp Defrost Installation Manual

The KE2 Temp Defrost Installation Manual provides step-by-step instructions for installing and configuring the controller for medium-temperature applications with air defrost. It includes wiring diagrams, sensor placement guidelines, and defrost cycle setup. The manual ensures proper installation to maintain optimal performance and energy efficiency. Detailed troubleshooting sections help resolve common issues, while clear navigation through the user interface simplifies setup. This guide is essential for technicians and installers to ensure seamless integration of the KE2 Temp Defrost system.

8.2 KE2 Evap OEM Controller Guide

The KE2 Evap OEM Controller Guide offers detailed instructions for integrating and operating the evaporator controller. It covers wiring diagrams, sensor connections, and system configuration. The guide emphasizes proper installation techniques to ensure efficient operation. Troubleshooting sections address common issues, while setup instructions simplify the process. This manual is tailored for OEMs and technicians, providing essential information to maximize the controller’s performance and reliability in various refrigeration applications.

8.3 KE2 CaseControllerDisplay (Ethernet) Instructions

The KE2 CaseControllerDisplay (Ethernet) Instructions provide a step-by-step guide for setting up and using the Ethernet-enabled display. It covers network configuration, pairing with controllers, and troubleshooting connectivity issues. The manual includes detailed diagrams and setup procedures to ensure seamless integration. Users can learn how to reset the display, update firmware, and navigate the interface efficiently. This guide is essential for optimizing remote monitoring and control capabilities of KE2 Therm systems.

Accessories and Compatibility

Explore compatible sensors, connectors, and optional high-amperage contact panels designed to enhance system performance and flexibility, ensuring seamless integration with KE2 Therm controllers and accessories.

9.1 Compatible Sensors and Connectors

KE2 Therm offers a range of compatible sensors and connectors to ensure optimal system operation. These include temperature sensors, spade connectors, and high-voltage safety shields. The Adaptive Control kit (pn 21177) provides 15′ temp sensors, spade connectors, and self-tapping screws for secure installations. Additional accessories like knockout plugs and air sensor mounts enhance flexibility. All components are designed to simplify the installation process and ensure seamless compatibility with KE2 Therm controllers, providing reliable performance and ease of use.

9.2 Optional Contact Panels for High Amperage Applications

KE2 Therm offers optional contact panels designed for high amperage applications, ensuring safe and efficient operation. These panels are pre-tested and ready for installation, providing reliable performance in demanding environments. They are ideal for systems requiring higher current handling capabilities. For specific details, contact KE2 Therm directly to discuss your requirements and ensure compatibility with your setup. These panels are recommended for users needing enhanced durability and performance in industrial or large-scale refrigeration systems.

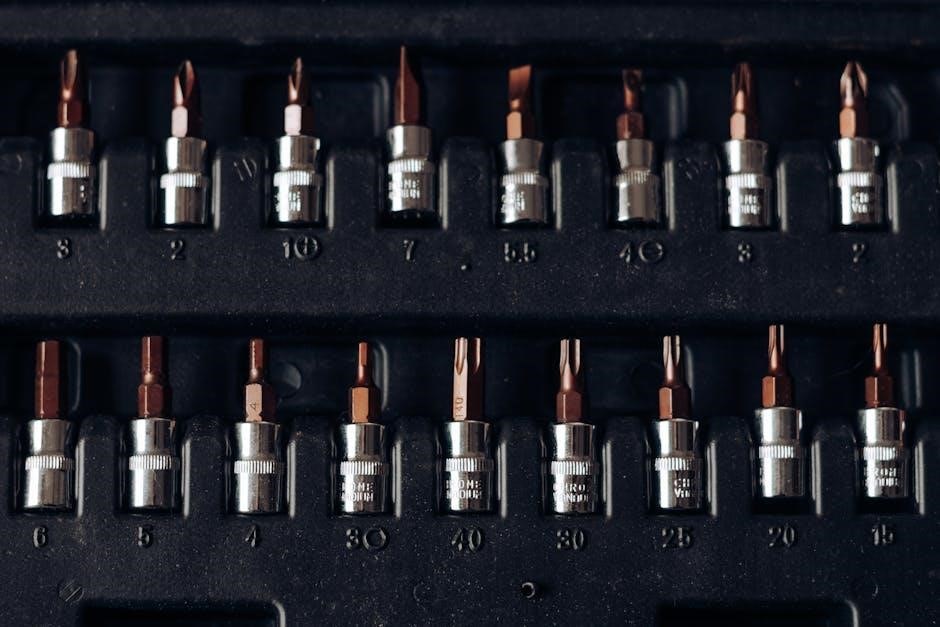

9.3 Additional Tools for Installation

For a seamless installation, KE2 Therm recommends using specific tools such as 90 spade connectors, self-tapping screws, and plastic knockout plugs. These tools ensure secure wiring and mounting. Additional accessories like conduit connectors and air sensor mounts are also available to simplify the process. Refer to the wiring diagrams and product-specific manuals for detailed guidance. Proper use of these tools ensures optimal system performance and longevity. Always consult KE2 Therm resources for compatible tools and installation best practices.

Safety and Compliance

Ensure compliance with industry standards and safety regulations when installing KE2 Therm products. Always follow proper wiring and safety precautions to avoid hazards and ensure reliable operation.

10.1 Safety Precautions for Installation and Use

Always disconnect power before starting installation to ensure safe working conditions. Follow all safety guidelines and industry standards to prevent electrical hazards. Properly ground the system to avoid shock risks. Keep liquids away from electrical components to prevent damage or short circuits. Use appropriate tools and wear protective gear when handling equipment. Ensure all connections are secure and meet local codes. Consult the manual for specific precautions related to defrost cycles and sensor placement.

10.2 Compliance with Industry Standards

KE2 Therm products are designed to meet or exceed industry standards, ensuring reliability and safety. They comply with certifications like UL, CE, and ETL, adhering to global regulations. All controllers and components are built to meet environmental and safety standards, such as RoHS. Regular updates and third-party testing ensure ongoing compliance. This ensures that users can trust the performance and safety of KE2 Therm solutions in various applications, from commercial refrigeration to industrial settings, while maintaining environmental responsibility and regulatory adherence.

10.3 Best Practices for System Maintenance

Regular system maintenance ensures optimal performance and longevity of KE2 Therm products. Schedule periodic checks of sensors, wiring, and controllers to prevent issues. Clean sensors and components to avoid interference. Update firmware and software regularly for the latest features and security. Refer to the manual for specific maintenance routines tailored to your system. Proper maintenance not only extends equipment life but also ensures energy efficiency and reliable operation, minimizing downtime and service costs. Always follow safety guidelines during maintenance procedures.

Maintenance and Upkeep

Regular maintenance ensures optimal performance and extends the lifespan of KE2 Therm systems. Perform routine inspections, clean components, and update firmware to maintain efficiency and reliability.

11.1 Regular Checks for Optimal Performance

Regular checks are essential to ensure the KE2 Therm system operates efficiently. Verify sensor accuracy, inspect wiring for damage, and ensure proper connections. Check defrost cycles and update firmware regularly. Clean components to prevent dust buildup and maintain airflow. Review alarm logs to address potential issues early. Schedule routine maintenance to extend system lifespan and prevent unexpected downtime. These checks help maintain energy efficiency and reliability, ensuring consistent performance across all applications.

11.2 Cleaning and Replacing Components

Regular cleaning of sensors and components ensures accurate performance. Use compressed air to remove dust from sensors and electrical connections. Replace worn or damaged wires and connectors promptly. For faulty components, refer to the product-specific manual for replacement procedures. Always power down the system before performing maintenance. Use genuine KE2 Therm replacement parts to maintain reliability. Follow proper safety precautions to avoid damage or electrical hazards. Replace components as recommended by the manufacturer to ensure optimal system operation and longevity.

11.3 Updating Firmware and Software

Regular firmware and software updates are crucial for maintaining optimal performance and security. Visit the official KE2 Therm website to download the latest updates. Ensure the system is powered down before starting the update process. Use the KE2 Smart Access tool for remote updates if available. Always verify the compatibility of the firmware with your specific controller model. Avoid using third-party sources to ensure authenticity and reliability. After updating, restart the system to apply changes and confirm proper functionality through diagnostic checks.

This manual provides essential guidance for KE2 Therm products, ensuring efficient operation and troubleshooting. For further assistance, visit the official KE2 Therm website or contact support.

12.1 Summary of Key Points

The KE2 Therm manual provides detailed guidance on installation, operation, and troubleshooting of KE2 Therm products. It emphasizes energy efficiency, adaptive control technology, and remote monitoring features. Users can customize defrost cycles, adjust temperature setpoints, and integrate smart access for enhanced functionality. The manual also includes sections on safety, compliance, and maintenance to ensure optimal performance. For further support, additional resources and product-specific manuals are available on the KE2 Therm website or through authorized distributors.

12.2 Additional Resources for Further Learning

For deeper understanding, visit the official KE2 Therm Solutions website to access downloadable PDF manuals, quick start guides, and technical bulletins. Additional resources include support.ke2therm.net for troubleshooting and FAQs. Refer to product-specific guides like the KE2 Temp Defrost Installation Manual and the KE2 Evap OEM Controller Guide for detailed instructions. Contact KE2 Therm Support directly for personalized assistance or clarification on advanced configurations and features.