Miele Induction Hob Manual: A Comprehensive Guide (Updated December 24‚ 2025)

This manual details Miele induction hob operation‚ including features like automatic cooker hood adjustment (Con@ctivity) and quick boiling capabilities‚ ensuring optimal performance.

Miele induction hobs represent a pinnacle of culinary technology‚ seamlessly blending sophisticated design with exceptional performance. These appliances are engineered for precision‚ efficiency‚ and user convenience‚ offering a superior cooking experience. Miele’s commitment to quality extends to its induction hob range‚ featuring models like the KM7361 and KM7363 FL‚ known for their sleek aesthetics and advanced functionalities.

Beyond basic cooking‚ Miele induction hobs offer innovative features such as automatic pan detection and connectivity with Miele cooker hoods via Con@ctivity. This allows for automated adjustment of the hood’s settings based on the cooking activity below. Understanding the nuances of your Miele induction hob is key to unlocking its full potential‚ and this guide will provide comprehensive instructions for optimal use and maintenance.

Understanding Induction Cooking Technology

Induction cooking utilizes electromagnetic energy to directly heat cookware‚ offering significant advantages over traditional methods. Unlike gas or electric hobs‚ induction doesn’t heat the hob surface itself; instead‚ it creates a magnetic field that interacts with ferromagnetic pots and pans. This results in faster heating times‚ precise temperature control‚ and improved energy efficiency.

Miele induction hobs are designed to recognize suitable cookware automatically‚ ensuring only compatible items activate the heating zones. This ‘automatic pan detection’ enhances safety and prevents wasted energy. The technology’s responsiveness allows for near-instant adjustments to heat levels‚ providing cooks with unparalleled control. Understanding this core principle is crucial for maximizing the benefits of your Miele induction hob.

Safety Precautions & Important Warnings

Prioritize safety when operating your Miele induction hob. The surface can become hot from the heat transferred from cookware‚ even if the hob itself doesn’t feel warm. Individuals with pacemakers or other medical implants should consult their physician before using induction cooking appliances due to the electromagnetic field.

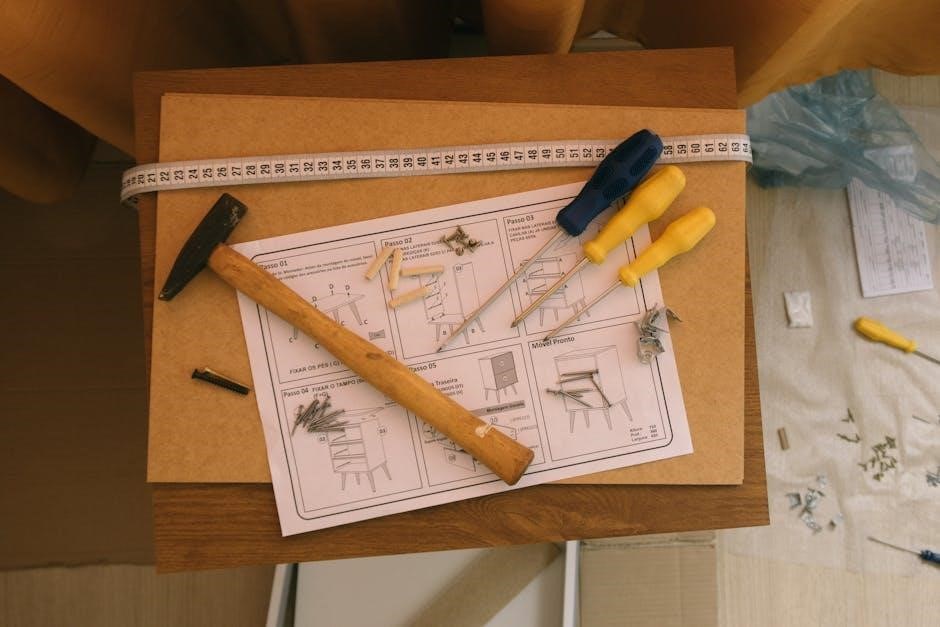

Always ensure cookware is suitable for induction – ferromagnetic materials are required. Never place metal objects on the hob when it’s not in use. Exercise caution when cooking with flammable liquids. Do not attempt to repair the hob yourself; contact a qualified Miele service technician for any maintenance or repairs. Keep the area around the hob clear of combustible materials.

Control Panel Overview & Symbols

The Miele induction hob’s control panel utilizes intuitive touch controls and clear symbols. Power on/off is typically indicated by a dedicated symbol‚ often a circle with a line. Timer functions are accessed via clock or hourglass icons‚ allowing precise cooking duration settings. Temperature control is managed through plus (+) and minus (-) symbols‚ adjusting power levels from low to boost.

Specific symbols denote special features like the keep warm or simmer functions. Understanding these icons is crucial for efficient operation. The panel may also display error codes‚ signaling potential issues. Refer to the troubleshooting section for detailed explanations of these codes. Familiarize yourself with the layout for seamless control.

Powering On/Off & Initial Setup

To power on your Miele induction hob‚ locate the dedicated power button – typically marked with a circle and vertical line. A brief press activates the control panel; a longer press may fully power down the unit. Initial setup often involves language selection and clock setting‚ guided by on-screen prompts.

Ensure the hob is correctly connected to a compatible power supply before initial use. Some models require a brief calibration process to optimize performance. Refer to the display for any specific setup instructions. Verify all cooking zones are clear before activation. Proper setup ensures safe and efficient operation from the start.

Understanding the Timer Functions

Miele induction hobs offer versatile timer functions for precise cooking control. A primary timer allows setting a duration for individual zones‚ automatically switching them off upon completion. A separate countdown timer functions independently‚ useful for reminding you of other tasks.

To set a zone timer‚ select the zone‚ then the timer icon. Input the desired cooking time using the control panel. The display will show the remaining time. Multiple timers can run concurrently. Explore the ‘Stop-and-Wait’ function for staged cooking. Mastering these timers ensures perfectly cooked dishes and prevents overcooking‚ enhancing your culinary experience.

Temperature Control & Power Levels

Miele induction hobs provide precise temperature control beyond simple power levels; While traditional settings range from 1-9 (lowest to highest)‚ many models offer a dedicated temperature selection mode‚ allowing you to set a specific temperature in degrees Celsius.

This is ideal for delicate tasks like melting chocolate or simmering sauces. Power levels dictate the heating rate; higher numbers mean faster heating. Automatic power boost features rapidly heat pans when needed. Understanding the relationship between power levels and temperature ensures optimal results for various cooking methods‚ maximizing efficiency and culinary precision.

Using the Various Cooking Zones

Miele induction hobs feature diverse cooking zones designed for flexibility. Standard single zones accommodate typical cookware sizes. However‚ many models boast dual zones and innovative Flex Zones‚ allowing you to combine areas for larger pots or irregularly shaped dishes.

The Bridge Function seamlessly connects adjacent zones‚ effectively creating a single‚ expansive cooking surface – perfect for griddles or multiple pans. Proper pan placement within designated zones is crucial for efficient heating. Experimenting with zone configurations maximizes space and adapts to diverse culinary needs‚ enhancing your cooking experience.

Single Zone Cooking

Utilizing single cooking zones on your Miele induction hob is straightforward. Ensure your cookware is compatible – possessing a ferromagnetic base is essential for induction heating. Center the pan on the zone’s marked circle for optimal energy transfer and efficient cooking.

Select your desired power level using the control panel; lower settings are ideal for simmering‚ while higher levels facilitate rapid boiling. The hob automatically detects the pan’s presence‚ activating the zone only when cookware is present. Remember to adjust cooking times based on the selected power level and the food being prepared for consistently delicious results.

Dual Zone & Flex Zones – Maximizing Space

Miele induction hobs often feature dual and flex zones‚ designed to accommodate larger or irregularly shaped cookware. Dual zones combine two smaller zones into one larger area‚ perfect for griddles or oversized pans. Flex zones offer even greater flexibility‚ creating a seamless cooking surface by merging multiple zones.

To activate these zones‚ consult your model’s specific instructions on the control panel. They allow for even heat distribution across the entire surface area of the combined zone. This is incredibly useful when preparing meals for larger gatherings or utilizing specialty cookware. Remember to center your cookware appropriately for optimal performance and safety.

Bridge Function – Connecting Zones

The bridge function on your Miele induction hob allows you to seamlessly connect two adjacent cooking zones‚ effectively creating one extended cooking surface. This is particularly useful for long‚ narrow cookware like roasting pans or griddles‚ ensuring even heat distribution across the entire length.

Activating the bridge function typically involves selecting the zones you wish to connect and then pressing a dedicated ‘bridge’ or ‘zone link’ symbol on the control panel. The hob will then treat the connected zones as a single unit‚ responding to a single temperature setting. Always ensure your cookware spans both zones when utilizing this feature for optimal results.

Special Features & Functions

Miele induction hobs boast a range of intelligent features designed to enhance your cooking experience. Automatic pan detection instantly recognizes cookware placed on the surface‚ activating the corresponding zone and optimizing heat transfer. The convenient keep warm function maintains food at a desired temperature‚ preventing it from cooling down prematurely.

For delicate simmering‚ the simmer function provides gentle and consistent heating‚ ideal for sauces and preventing burning. Furthermore‚ many models offer connectivity with Miele cooker hoods (Con@ctivity)‚ allowing for automatic fan speed adjustment based on the hob’s activity‚ ensuring a comfortable kitchen environment.

Automatic Pan Detection

Miele induction hobs utilize sophisticated sensors to automatically detect the presence of suitable cookware on the cooking zones. This feature eliminates the need for manual zone selection; the hob intelligently identifies the pan’s size and position‚ activating only the area directly underneath.

The system recognizes ferromagnetic materials – essential for induction cooking – ensuring efficient heat transfer. Once a pan is lifted‚ the zone automatically deactivates‚ enhancing safety and conserving energy. This intuitive function simplifies operation‚ providing a seamless and responsive cooking experience‚ and contributes to the hob’s overall efficiency.

Keep Warm Function – Maintaining Food Temperature

The Keep Warm function on your Miele induction hob is designed to maintain cooked food at a safe and enjoyable serving temperature without further cooking. Activated via the control panel‚ this feature reduces the power output to a low‚ consistent level‚ preventing food from cooling down too quickly.

Ideal for situations where meals are prepared in advance or staggered serving times are anticipated‚ the Keep Warm function ensures dishes remain palatable. It’s particularly useful for delicate items that are sensitive to overcooking. Remember to select an appropriate power level for optimal results‚ avoiding prolonged use for raw ingredients.

Simmer Function – Gentle & Consistent Heating

Miele induction hobs feature a dedicated Simmer function‚ providing exceptionally gentle and consistent heating – perfect for delicate sauces‚ soups‚ and dishes requiring prolonged‚ low-temperature cooking. Unlike traditional simmering methods‚ induction offers precise temperature control‚ preventing scorching or sticking.

This function maintains a very low power output‚ ideal for preventing food from boiling over or reducing rapidly. It’s particularly beneficial for recipes where slow‚ even heat distribution is crucial for flavor development. The Simmer function ensures your culinary creations are cooked to perfection‚ offering a reliable and convenient alternative to manual heat adjustments.

Connecting to a Miele Cooker Hood (Con@ctivity)

Miele’s Con@ctivity feature seamlessly integrates compatible induction hobs with Miele cooker hoods‚ creating a synchronized cooking environment. This wireless communication allows the hob to automatically adjust the hood’s fan speed based on the intensity of cooking. When you begin heating‚ the hood activates; as you increase power‚ the fan speeds up‚ efficiently removing odors and steam.

This intelligent system eliminates the need for manual adjustments‚ ensuring optimal ventilation throughout the cooking process. Con@ctivity provides a more convenient and responsive cooking experience‚ maintaining a comfortable kitchen atmosphere. Ensure both your hob and hood are Con@ctivity enabled for this feature to function correctly.

Automatic Hood Adjustment – How it Works

The automatic hood adjustment‚ powered by Con@ctivity‚ operates through a bi-directional wireless link between the Miele induction hob and a compatible cooker hood. The hob continuously monitors the selected power level and cooking zone usage. This data is then transmitted to the hood‚ which interprets it to determine the appropriate fan speed.

Lower power settings trigger lower fan speeds‚ while higher settings – like rapid boiling – automatically increase ventilation. The system isn’t solely based on power; it also considers the number of active zones. This ensures comprehensive and responsive air extraction‚ adapting to your specific cooking needs in real-time‚ creating a comfortable kitchen environment.

Troubleshooting Con@ctivity Issues

If Con@ctivity isn’t functioning‚ first ensure both the hob and cooker hood are Con@ctivity-enabled Miele models. Verify both appliances are powered on and within range – typically a few meters. Check for wireless interference from other devices‚ potentially disrupting the signal.

Restarting both appliances can often resolve temporary glitches. Within the hob’s settings‚ confirm Con@ctivity is activated. If problems persist‚ a factory reset of the Con@ctivity function (refer to the full manual) might be necessary. If the hood still doesn’t respond‚ consult a qualified technician‚ as deeper communication issues may require professional attention.

Cleaning & Maintenance

Maintaining your Miele induction hob ensures longevity and optimal performance. After each use‚ allow the surface to cool completely before cleaning. Use a soft cloth and mild detergent to wipe away spills and residue. Avoid abrasive cleaners or scouring pads‚ as these can damage the glass ceramic surface.

For stubborn stains‚ a dedicated ceramic hob cleaner is recommended. Regularly inspect the hob for any signs of damage. Preventative maintenance includes wiping down the surface daily. Descaling procedures‚ if applicable (refer to your model’s manual)‚ should be performed periodically to maintain efficiency and prevent buildup.

Recommended Cleaning Products

Miele strongly advises against abrasive cleaners‚ scouring pads‚ and harsh chemicals on your induction hob’s surface. These can cause permanent scratches and damage the glass ceramic. Instead‚ opt for Miele’s own ceramic hob cleaning products‚ specifically formulated for induction surfaces‚ ensuring effective cleaning without risk.

Mild dish soap and warm water are suitable for daily cleaning of minor spills. For tougher‚ burnt-on residue‚ a dedicated ceramic hob scraper (used carefully at a low angle) can be employed before applying a ceramic cleaner. Always follow the product instructions and rinse thoroughly with a clean‚ damp cloth after cleaning‚ leaving no residue.

Preventative Maintenance Tips

Regular cleaning is paramount to maintaining your Miele induction hob’s performance and longevity. Wipe up spills immediately to prevent burnt-on residue‚ which requires more intensive cleaning. Avoid sliding pots and pans across the surface‚ as this can cause scratches over time.

Ensure cookware has smooth‚ flat bottoms for optimal heat transfer and to minimize potential scratching. Periodically check the hob for any signs of damage‚ such as cracks or chips. Avoid placing heavy objects on the hob surface when it’s not in use. Following these simple steps will help preserve your Miele induction hob’s pristine condition.

Descaling Procedures

Although less frequent than routine cleaning‚ descaling your Miele induction hob may become necessary‚ particularly if you use hard water. Look for limescale buildup around the edges of the cooking zones. Miele recommends using a commercially available descaling solution specifically designed for induction hobs – always follow the manufacturer’s instructions carefully.

Apply the descaling solution to a soft cloth and gently wipe the affected areas. Avoid abrasive cleaners or scouring pads‚ as these can damage the glass surface. After descaling‚ thoroughly rinse the area with clean water and dry with a soft cloth. Regular preventative cleaning minimizes the need for descaling.

Troubleshooting Common Issues

Encountering problems with your Miele induction hob? This section addresses frequent concerns. If the hob isn’t heating‚ first check the power supply and ensure the cookware is induction-compatible. Error codes displayed on the control panel indicate specific issues; consult the detailed error code list within this manual for explanations and suggested solutions.

Connectivity problems with a Miele cooker hood (Con@ctivity) can often be resolved by restarting both appliances. If issues persist‚ verify the Con@ctivity settings are correctly configured. For more complex problems‚ refer to the dedicated Con@ctivity troubleshooting section or contact Miele’s customer support.

Error Codes & Their Meanings

Miele induction hobs utilize error codes to diagnose issues. A flashing code on the control panel signals a problem requiring attention. For example‚ code “E140” often indicates a communication error with a connected cooker hood‚ while “E205” suggests an issue with the internal temperature sensor.

Refer to the comprehensive table below for a complete list of error codes and their corresponding meanings. Each entry details the potential cause of the error and provides recommended troubleshooting steps. Ignoring error codes can lead to further damage; promptly address any displayed code to ensure optimal hob performance and longevity.

Hob Not Heating – Possible Causes

If your Miele induction hob isn’t heating‚ several factors could be at play. First‚ ensure the cookware is induction-compatible – non-magnetic pots and pans won’t work. Second‚ verify the hob is properly connected to a functioning power supply and the circuit breaker hasn’t tripped. Third‚ check if the correct cooking zone is selected and activated.

Further investigation may reveal a faulty control panel or a damaged heating element. If error codes are displayed‚ consult the “Error Codes & Their Meanings” section. For persistent issues‚ contacting Miele’s customer support or a qualified technician is recommended to diagnose and resolve the problem safely.

Connectivity Problems – Solutions

Experiencing issues with your Miele hob’s Con@ctivity feature? First‚ confirm both the hob and cooker hood are Miele Con@ctivity-enabled models. Second‚ ensure both appliances are powered on and within range for a stable wireless connection. Third‚ check the Con@ctivity settings on both devices – they must be properly paired.

If problems persist‚ try restarting both the hob and cooker hood. Verify there are no obstructions interfering with the wireless signal. Consult the manual for specific pairing instructions. For continued difficulties‚ contacting Miele support can provide tailored assistance to restore seamless communication between your appliances.